LABORATORY: ELECTRONICS AND MODERN INSTRUMENTATION:

Unit 1: Introduction to Basic Electronic Components. Test and Measurement Instruments

Introduction

In the designing of any electronic circuit, three most important considerations are:

This Unit deals with familiarization of basic components like resistors, Capacitors and diodes, followed by introduction to a few instruments like multimetrs and CRO. At the end a few experiments related with CRO have been explained.

Basic Components: Basic components like capacitors, resistors, inductors, diodes, light emitting diode (led) and transistors can be divided into 2 categories: (i) Passive components like resistors and capacitors and (ii) Active components like diodes and transistors. The difference between the above two categories is that active components can generate energy whereas passive components can not generate energy. In other words active components can increase power of a signal whereas passive components often cause the power to be lost.

Some components like resistors have their values marked on them whereas others like transistors do not have any value marking but have a type number on them. One has to refer to datasheets to get to know the value of the unmarked component. Besides component values, they are also characterized by their ratings for e.g. maximum current value that a component can stand without being burnt out.

Resistors: Resistors can be of two types: fixed value resistors or variable resistors. The formula for resistance is given by: R = ρ l / A where ρ is resistivity, l is length and A is area of crossection. Different value resistors can be manufactured by changing the length and area of crossection or the material itself which changes the resistivity. Materials generally used for fabrication of resistors are nichrome (80 % Ni and 20 % Cr), constatntan (55% cu and 45 % Ni ) and Manmganin (85 % Cu and 10 % Mn and < 5 % Ni). Metals are not used as they have a very high temperature coefficient of resistance. Three main methods of fabrication are (i) a slab or a rod of suitable resistivity, (ii) Material using thinner crossection and longer length. The length is doubled and then wound in such a way that inductance effects are cancelled out. (iii) Thin films of material on insulating substrate. Each resistor has a current carrying capacity. Current more than the prescribed wattage may damage the resistor.

Colour Code for Resistors

Band colour & its value |

Band colour & its tolerance |

Black = 0 |

Gold = + - 5% |

The first two bands near an end indicate first 2 digits, digit corresponding to 3rd band is the power of 10 to be multiplied and fourth band indicates tolerance as mentioned in the table. Refer fig 1, where brown = 1, black = 0, red = 2 and silver = 10 % tolerance. Hence its value is

10 x 10 2 Ω = 1 k Ω.

Most commonly used resistors in lab are fixed value resistors which exist for standard values according to E12. Other ranges are E24 and E48 Ranges.

E12 Range: Table 1 is for the values of resistors of E12 range. Topmost row defines the basic value units of resistors in ohms. Every following row is 10 fold of the upper row.

Table 1: Table for E12 range values of resistors.

1.0 Ω |

1.2 |

1.5 |

1.8 |

2.2 |

2.7 |

3.3 |

3.9 |

4.7 |

5.6 |

6.8 |

8.2 Ω |

10 Ω |

12 |

|

. |

. |

|

. |

. |

|

|

68 |

82 Ω |

100 Ω |

|

|

|

|

|

|

|

|

|

680 |

820 Ω |

1k |

1.2k |

|

|

|

|

|

|

|

|

6.8k |

8.2k |

10k |

|

|

|

|

|

|

|

|

|

|

82k |

100k |

|

|

|

|

|

|

|

|

|

|

820k |

1M |

1.2M |

|

|

|

|

|

|

|

|

6.8M` |

8.2M |

10M |

12M |

|

|

|

|

|

|

|

|

68M |

82M |

Variable resistors Besides the fixed value resistors, there also exist variable resistors. The resistance of variable resistors can vary in steps or continuously. Potentiometer is also an example of continuously varying resistor

Special purpose resistors Light dependent resistors (LDR) and thermistors are examples of special purpose resistors. Thermistor is a resistor whose value depends on its temperature. It is also called a heat sensor. LDR is a resistance whose resistance depends upon the amount of light falling on it.

Capacitors

Capacitors are capable of storing charges. They are used for coupling ac signals from one circuit to another and for frequency selection etc. A capacitor consists of 2 metallic plates separated by a dielectric. The capacitance is defined as : C = Єo Єr A / d, where A is the area of plates, d is plates separation, Єo is permittivity of free space and Єr is relative permittivity. An important parameter for capacitors is its voltage handling capacity beyond which the capacitor dielectric breaks down.

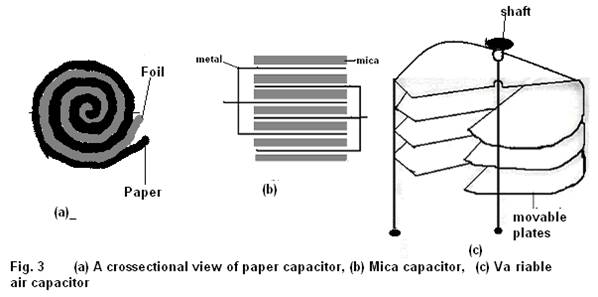

The value of a capacitor depends upon the dielectric constant (K = Єo Єr.) of the material. There are three main classes of capacitors: (i) Non electrolytic or normal capacitors and (ii) electrolytic capacitors and (iii) variable capacitors. Normal capacitors are mostly of parallel plate type and can have mica, paper, ceramic or polymer as dielectric. In the paper capacitors two rectangular metal foils are interleaved between thin sheets of waxed paper and the whole system is rolled to form a compact structure. Each metal foil is connected to an electrode. In mica capacitors alternate layers of mica and metal are clamped tightly together. Refer fig 3.

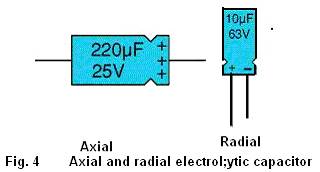

In electrolytic capacitor mostly a then metal-oxide film is deposited by means of electrolysis on axial electrode. That’s how it derives its name. During electrolysis the electrode acts as anode whose cathode is a concentric can. Since the dielectric layer is very thin hence these require special precaution for their use: i.e. they have to connected in the right polarity failing which the dielectric breaks down. Besides these fixed value capacitors we also have variable capacitors whose value depends upon the area of crossection. They have a fixed set of plates and a movable set of plates which can be moved through a shaft. This movement changes the area of overlap of the two sets of plates which changes its capacity. Refer fig 3.

Colour and Number code of capacitors. Different marking schemes are used for electrolytic and non-electrolytic capacitors. Temperature coefficient is of minor importance in an electrolytic filter capacitor, but it is very important in ceramic trimmers for attenuator use. One never finds temperature coefficient on an electrolytic label, but it is always present on ceramic trimmers.

Capacitor Colour Code: Sometimes capacitors just show bands like resistors when printing is tough on them. The colours should be read like the resistor code, the top three colour bands giving the value in pF. The 4th band and 5th band are for tolerance and voltage rating respectively. For example: brown, black, orange means 10000pF = 10nF = 0.01µF.

Available Values of Capacitors: Like resistors capacitors are also available for only particular values. Following are 2 series defined for capacitors

The E3 series (3 values for each multiple of ten) 10, 22, 47, then it continues 1to100, 220, 470, 1000, 2200, 4700, 10000 etc.

The E6 series (6 values for each multiple of ten) 10, 15, 22, 33, 47, 68, ... then it continues 100, 150, 220, 330, 470, 680, 1000 etc.

Inductors: Inductor is a component made by a coil of wire which is wound on a core. It is used to vary the impedance of a circuit or for frequency tuning. The value of an inductor depends upon the total number of turns (N), area of crossection of the core (A) and length of the core (l).The formula is L = μo μr N2 A / l. Its unit is in Henry.

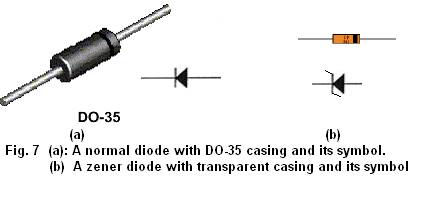

Diode: A diode is a single junction device made of p and n type materials.. Its main function is to rectify an ac signal although other special purpose diodes like zener and led’s are used for other purposes. A normal diode comes in a black casing whereas a zener diode has a transparent casing. Their pictures and symbols are given in fig. 7.

Other diodes may be made by a p type and n type materials or between a semiconductor and a metal. If the junction is made between a metal and semiconductor then it is called a Schottky diode whose application is in rectifying and non-rectifying contacts and Schottky devices. If the pn junction is made between very heavily doped materials then it forms a Zener diode. These are used for voltage regulation in power supplies. and have breakdown voltages which are very low. The normal diode has a breakdown voltage of greater than 100 V.

Some of the diode specifications are: Maximum reverse voltage (Vbr), rated forward current (If) , maximum forward voltage drop (Vf) and package style. Table 3 gives some of the most commonly used diodes with their specifications.

Table 3

Device Number |

Material used. |

IF (mA) |

VF(V) |

VBR |

OA91 |

Ge |

50 |

2.1 |

115 |

In 4148 |

Si |

100 |

1.0 |

75 |

In 4149 |

Si |

100 |

1.0 |

75 |

IN 4007 |

Si |

1000 |

1.6 |

1000 |

To test whether a given diode is O.K. or not, a simple multimter test can be performed which is given later in this unit.

Light Emitting Diode (LED)

Led’sare pn junction devices which emit light radiation when biased in the forward direction. The semiconductor material used for these junctions is a compound semiconductor like AlGaAs whose band gap corresponds to a particular wavelength according to equation Eg = 1.24 / λ where Eg is the band gap in ev and λ is the wavelength in microns. (e.g. red ~ 0.7 μ hence corresponding E g = 1.24 / 0.7 = 1.77 ev). When the pn junction is forward biased, the electrons are excited to conduction band and when they fall to the valence band, they give out energy in the form of radiation corresponding to the Eg of the material Conventional led’s are made from the materials like AlGaAs, GaAlP, GaAsP, GaP and GaN which emit Red, green, orange, yellow and blue colours respectively. Led’s come in a special transparent casing as shown in fig 8..Dual colour led’s are also available where two junctions are encapsulated on the same chip. It has three leads where cathode is common whereas normal leds’ have two leads one for cathode and other for anode. A very important precaution while using an led is the amount of current being passed through it. For most leds the maximum allowable current is 20 mA beyond which the led can burn out. Hence in most of the circuits a resistor is used to limit the current. Some important specifications before using an led are: LED colour, peak wavelength, viewing angle, optical power output, luminous intensity, forward current and forward voltage.

Transistors

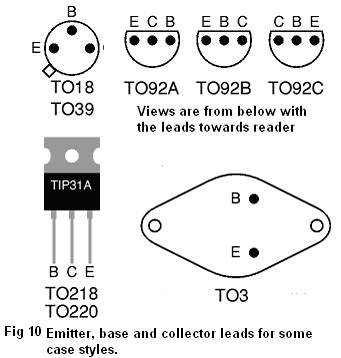

Transistors are semiconductor devices used for applications like amplification of voltages, current and are also used in oscillator circuits and switches. It’s a two junction and 3 terminal device made of three layers of n and p type materials. The three regions are emitter, base and collector. They are of 2 types (i) pnp and (ii) npn. Their most important specifications are Ic, Vce, hfe and Power rating. They come in different casings like TO18, TO92C, and TO39 etc Given below is a table of most commonly used transistors with their specifications (approximate) and casings. Datasheets from the companies can be referred to to know the exact specifications.

Code |

Structure |

Case |

IC |

VCE |

hFE |

Ptot |

Category |

Possible |

BC107 |

NPN |

TO18 |

100mA |

45V |

110 |

300mW |

Audio, low power |

BC182 BC547 |

BC108 |

NPN |

TO18 |

100mA |

20V |

110 |

300mW |

General purpose, low power |

BC108C BC183 BC548 |

BC108C |

NPN |

TO18 |

100mA |

20V |

420 |

600mW |

General purpose, low power |

|

BC109 |

NPN |

TO18 |

200mA |

20V |

200 |

300mW |

Audio (low noise), low power |

BC184 BC549 |

BC182 |

NPN |

TO92C |

100mA |

50V |

100 |

350mW |

General purpose, low power |

BC107 BC182L |

BC182L |

NPN |

TO92A |

100mA |

50V |

100 |

350mW |

General purpose, low power |

BC107 BC182 |

BC547B |

NPN |

TO92C |

100mA |

45V |

200 |

500mW |

Audio, low power |

BC107B |

BC548B |

NPN |

TO92C |

100mA |

30V |

220 |

500mW |

General purpose, low power |

BC108B |

BC549B |

NPN |

TO92C |

100mA |

30V |

240 |

625mW |

Audio (low noise), low power |

BC109 |

2N3053 |

NPN |

TO39 |

700mA |

40V |

50 |

500mW |

General purpose, low power |

BFY51 |

BFY51 |

NPN |

TO39 |

1A |

30V |

40 |

800mW |

General purpose, medium power |

BC639 |

BC639 |

NPN |

TO92A |

1A |

80V |

40 |

800mW |

General purpose, medium power |

BFY51 |

TIP29A |

NPN |

TO220 |

1A |

60V |

40 |

30W |

General purpose, high power |

|

TIP31A |

NPN |

TO220 |

3A |

60V |

10 |

40W |

General purpose, high power |

TIP31C TIP41A |

TIP31C |

NPN |

TO220 |

3A |

100V |

10 |

40W |

General purpose, high power |

TIP31A TIP41A |

TIP41A |

NPN |

TO220 |

6A |

60V |

15 |

65W |

General purpose, high power |

|

2N3055 |

NPN |

TO3 |

15A |

60V |

20 |

117W |

General purpose, high power |

|

BC177 |

PNP |

TO18 |

100mA |

45V |

125 |

300mW |

Audio, low power |

BC477 |

BC178 |

PNP |

TO18 |

200mA |

25V |

120 |

600mW |

General purpose, low power |

BC478 |

BC179 |

PNP |

TO18 |

200mA |

20V |

180 |

600mW |

Audio (low noise), low power |

|

BC477 |

PNP |

TO18 |

150mA |

80V |

125 |

360mW |

Audio, low power |

BC177 |

BC478 |

PNP |

TO18 |

150mA |

40V |

125 |

360mW |

General purpose, low power |

BC178 |

TIP32A |

PNP |

TO220 |

3A |

60V |

25 |

40W |

General purpose, high power |

TIP32C |

TIP32C |

PNP |

TO220 |

3A |

100V |

10 |

40W |

General purpose, high power |

TIP32A |

Fig 9 gives some of the transistors with the symbols. for npn and pnp. and fig 10 illustrates some of the casings. with the configurations for emitter , base and collector leads

Integrated Circuits (IC)

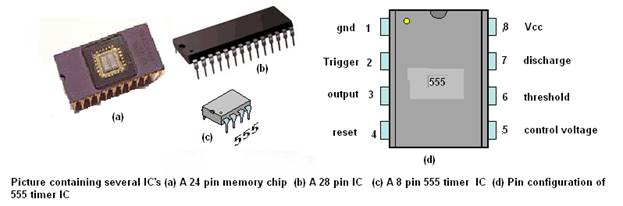

Integrated Circuit (IC) Today all electrical, electronic and computer parts have IC’s in them. Integrated circuit is a name given to a package which can hold more than 10 and up to millions of electronic components. They can give various functions like : (i) the function of a full microprocessor circuit (eg 8085), (ii) a memory chip, (iii) a voltage regulator (LM 7805) or (iv) Can contain just 10 AND gates (eg LS7400). They come in a black bench like casing with a notch on one side and with electrical legs for connections, which are called pins. The size is usually around 1 cm2 X 1 cm2. Refer to the picture. Its name is always written on top which contains a few letters with numerals, according to its type, make and company. For example an IC with name LS 7400 would mean LS series with And gates, LM741C - mA741C is an operational amplifier (opamp). Datasheets can be referred to, to know the details of pin configurations and make etc. The pins are usually read starting from left of notch and going anticlockwise as shown in picture for 555 timer IC.

Fabrication of an IC is a highly sophisticated and expensive process requiring clean rooms and very expensive equipments like photolithography, metallization and diffusion etc. But because of their bulk manufacture and requirement the cost of each IC is very low.

Instruments:

Multimeters: A multimeter is an instrument which measures electrical parameters such as AC or DC voltage, current, and resistance. Rather than having separate meters, a multimeter combines a voltmeter, an ammeter, and an ohmmeter. The two main kinds of a multimeter are analog and digital. Refer fig 10. A digital multimeter has an LCD screen that displays the value of the parameter being measured. while in an analog multimeter display, a needle moves through a graduated scale. Topmost scale is usually for resistance and the readings increases from right to left while other scales readings increase from left to right. Another name for an analog multimeter is Volt-Ohm-Milliammeter (VOM). Each type of meter has its advantages and disadvantaged. When used as a voltmeter, a digital meter is usually better because its resistance is much higher, 1 M or 10 M, compared to 200 Ω for an analogue multimeter for a similar range. On the other hand, it is easier to follow a slowly changing voltage by watching the needle on an analogue display. Most modern multimeters are digital and traditional analogue types are becoming obsolete

Block diagram of a VOM is given in fig. 11

Voltage measurement by multimeter: For the case of a VOM, a zero adjustment has to be made every time the multimeter is to be used. To do the zero adjustment, set the mode selection knob in resistance mode. Connect the two leads to positive and common terminals respectively and short the leads. The needle should move to extreme right to the last reading on the ohms scale. If it stops before or goes beyond then the zero adjustment knob has to be rotated (clockwise or anticlockwise) such that the needle rests at the last reading on the right end of the bar on the ohms scale. Subsequently, to measure voltage, the multimeter has to be first set in AC or DC mode. After selecting a suitable range defined by the uppermost limit of the expected value, the range knob has to be set. Next connect the common (gnd) terminal through a lead (black) to the gnd of the circuit and the red lead to the point where voltage is to be measured. For the case of an analogue multimeter, if the needle goes the wrong way the leads have to be reversed or if the needle doesn’t move at all the range has to be changed. To find the value of the voltage, read the number from that scale that matches the range being used. In a digital multimeter, if 1. is displayed then the range has to be increased..

Resistance Measurement: To measure resistance in a circuit, first the power supply is to be turned off (or disconnected) otherwise the multimeter might get damaged. Next, select a range on the multimeter and touch two metal points in the circuit. If the needle doesn’t move or goes all the way to the end of the scale, select another range. One can not use this method to measure the resistance of a resistor in the circuit because there may be other paths between the nodes of a resistor. One leg of a resistor must be disconnected from the circuit to make sure that the only path between the two probes is through that resistor. To measure the resistance of a resistor, select the range on the meter that might be closest to the right value and use the probes to touch either side of the resistor. If the right range is selected then the needle will be somewhere between the left and the right end of the scale. To find the value of the resistor, read the number from the scale that matches the range you are using.

MULTIMETER TEST OF DIODES

One can know whether a specific terminal of a diode is n or p by measuring the resistance with multimeter. To do so keep the multimeters in resistance mode connect its positive lead to the anode of diode and negative lead to its cathode. During the test, the multimeter passes current through the diode and the diode gets forward biased. It thus indicated very low resistance of the order of 100 W . If the leads are now reversed than the diode gets reverse biased and offers very high resistance of the order of MW. This can be read in the multimeter again. If a diode reads very low resistance in the forward as well as reverse bias then it is shorted. On the other hand if it reads high resistance in the forward as well as reverse bias then it is open.

FUNCTION GENERATORS

Function Generators are instruments capable of generating an ac signal of any frequency (~ 100Hz – hundreds of kHz), voltage(~1 mv – 20V) and various forms (e.g. sine wave, Square pulse, Saw tooth wave, Triangular wave or noise waveform). They also provide a continuously variable dc offset, variable duty cycle. They are usually of 2 types: (i) analog and (ii) Digital.

Some of the front panel controls of a typical function generator are:

1 Power Switch For switching obn the power supply

2 Digital Display This is a 4 digit frequency meter

3 OFFSET This knob is for adding a dc voltage to the output signal

4 Amplitude This does the continuous adjustment of output voltage

5 Speed This is for setting wobulation speed

6 Width This knob is for setting the wobulation width

7 Frquency This knob is for selecting the frequency range from 0.3 Hz to 3MHz in decade steps.

8. Sweep On This is a push button for activating internal sweep

9 Mode Selection Push Button for triangular, sine Square etc.

10 BNC connector This is a 50 Ω output BNC connector

11 -20 db, - 20 db A push button control for -20 db attenuation. When both buttons are pushed then a total of 40 db attenuation is got.

Cathode Ray Oscilloscope (CRO)

CRO is an instrument which is used to measure voltages that change with time and to display the waveforms in real time mode. There is a graphical scale present on the screen which is used to calculate the voltage or frequency value. A very important specification of a CRO is its bandwidth which gives the maximum frequency of a signal which a CRO can measure. A simple oscilloscope consists of a cathode ray tube, a vertical amplifier, a time base, a horizontal amplifier and a power supply. Fig 12 shows the block diagram of a CRO. Cathode-ray tube is a vacuum tube in which a beam of electrons is produced and focused onto a fluorescent screen. The electrons’ kinetic energy is converted into light energy as they collide with the screen. It is an essential component of television receivers, computer visual display units, and CRO. Between the electron gun and the screen are two pairs of metal plates : (i) Horizontal Deflection Plates and (ii) Vertical deflection plates. These are driven by Horizontal Deflection system and Vertical deflection system respectively.

In the vertical deflection system, the vertical amplifier is driven by an external voltage (the vertical input) that is to be measured. The amplifier has very high input impedance, typically one megohm, so that it draws only a tiny current from the signal source. The amplifier drives the vertical deflection plates with a voltage that is proportional to the vertical input. The gain of the vertical amplifier can be adjusted to suit the amplitude of the input voltage. A positive input voltage bends the electron beam upwards, and a negative voltage bends it downwards, so that the vertical deflection of the dot shows the value of the input. The horizontal deflection system consists of a time base circuit which is an electronic circuit that generates a ramp voltage (saw tooth waveform) . Refer fig. 13.

In the vertical deflection system, the vertical amplifier is driven by an external voltage (the vertical input) that is to be measured. The amplifier has very high input impedance, typically one megohm, so that it draws only a tiny current from the signal source. The amplifier drives the vertical deflection plates with a voltage that is proportional to the vertical input. The gain of the vertical amplifier can be adjusted to suit the amplitude of the input voltage. A positive input voltage bends the electron beam upwards, and a negative voltage bends it downwards, so that the vertical deflection of the dot shows the value of the input. The horizontal deflection system consists of a time base circuit which is an electronic circuit that generates a ramp voltage (saw tooth waveform) . Refer fig. 13.

This is a voltage that changes continuously and linearly with time. When it reaches a predefined value the ramp is reset. When a trigger event is recognized the reset is released, allowing the ramp to increase again. The time base voltage usually drives the horizontal amplifier. Its effect is to sweep the electron beam at a constant speed from left to right across the screen, then quickly return the beam to the left in time to begin the next sweep.

This is a voltage that changes continuously and linearly with time. When it reaches a predefined value the ramp is reset. When a trigger event is recognized the reset is released, allowing the ramp to increase again. The time base voltage usually drives the horizontal amplifier. Its effect is to sweep the electron beam at a constant speed from left to right across the screen, then quickly return the beam to the left in time to begin the next sweep.

CRO controls from the front panel

1 Intensity This knob controls the brightness of the trace by adjusting the number of electrons emerging from the gun

2 Focus This control is for making the trace on the screen sharper. It is connected to the anode of the electron gun whose voltage collimates the electron beam.

3 Vertical Position & Horizontal Position Through these controls the beam can be positioned at variable vertical or horizontal positions as desired. These knobs apply a dc voltage to the vertical and horizontal deflection plates.

4 V / Div. This control is used to control the voltage sensitivity. This is internally connected to an attenuator of the vertical system. It determines the voltage required by the vertical plates to deflect the beam vertically by one division.

5 Time / Div This determines the time taken for the spot to move horizontally across one division of the screen when the sweep is generated by triggering process. The signal which is fed to the vertical deflection plates provides the triggering to the waveform. Each position of the time/ div knob is applicable for a particular frequency. This determines the horizontal sensitivity of the observed signal.

6 Trigger Source This selects the source of the trigger to be applied to the saw tooth waveform. There are usually three possible sources (i) Internal: This is mostly used for all applications. The vertical signal applies the triggering signal. (ii) Line: This is generally used when the voltage to be measured is related to the line voltage. This selects the 50Hz line voltage. (iii) Ext. In this case an external signal is applied to trigger the saw tooth waveform./

7 Slope This determines whether the time base circuit responds to the positive or negative slope of the triggering waveform.

8 Level This determines the amplitude level on the triggering waveform which can start the sweep

9 AC, DC, GND: This selects the coupling mechanism for the input signal to the CRO. In dc mode the vertical amplifier receives both ac and dc components of the input signal. In ac mode the coupling capacitor blocks all dc components and displays only pure ac waveform. In gnd configuration, the input signal is grounded and one gets a straight line. To measure the dc component of any signal (ac or dc), one has to switch from ac to dc mode and observe the vertical shift of the waveform. The amount of vertical shift in volts gives the corresponding dc component.

10 X-Y mode: In this mode of operation. two signals are superimposed at right angles on each other. The saw tooth time base circuit is disconnected from the horizontal deflection plates and the external signal which s fed to channel two is given to time base instead. Hence if two sine waves are fed to two channels respectively then the electron beam will undergo deflection according to right angle superposition of two sine waves. It will trace lissajous figures.

Few experiments related with CRO:

Objective To measure voltage and frequency of an ac signal

Voltage measurement To measure the voltage of an ac waveform, connect the ac signal from signal generator to CRO channel 1 such that a stable waveform such as that of fig 14. is displayed. Here Vpp is the peak to peak voltage and Vm is the maximum voltage.

Suppose volts / div is at 1V scale then Vpp = 4 div x 1 V = 4V

and Vm = 2div x 1V = 2V.

The effective value is V effec = V rms= Vm X 0.7. = 1.4 V

If an ac voltmeter is connected across the signal it will give the same value i.e.1.4V.

Frequency Measurement The distance covered by one wave in fig. 14 , gives the time period (T) of the waveform.

Suppose time / div knob is at 1 ms scale then T = 2div x 1 ms = 2 msec.

Hence frequency (F) = 1 / T = 1 / 2msec = 0.5 kHz = 500 Hz.

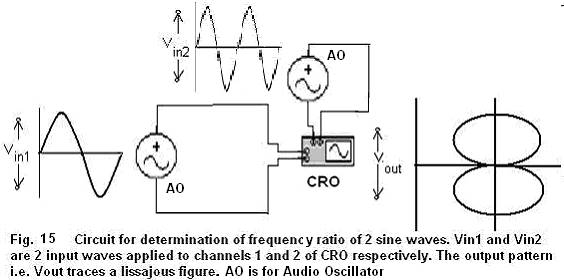

Objective To measure frequency ratio and measure phase difference of 2 waveforms using lissajous figures.

Lissajous Figures

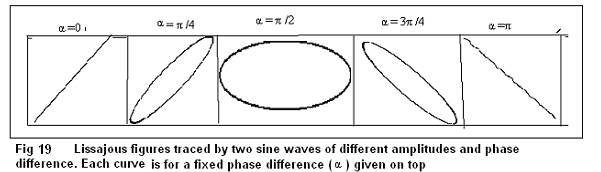

When a particle is influenced by two simple harmonic motions which are at right angles to each other then it traces a curve called lissajous figure. For the case of a CRO, when the time base of the CRO is not applied to the horizontal (X) plates, any waveform can be applied across these plates. If different sine waves are applied to the X and Y plates, a stationary pattern is traced by the electron beam. This pattern depends on the ratio of the frequencies of the two waves ( i.e. 1: 1, 1:2, 1:3 or 1:4 etc.) and the phase difference between the two waves. The frequency ratio of 1:1 gives a circular pattern if the signals (i) have the same amplitudes and (ii) are 90° out of phase. A phase difference of 45o produces an ellipse, and zero phase difference produces a straight line inclined at an angle determined by the magnitudes of the two signals.

Measurement of Frequency Ratio

For measurement of frequency ratio refer to circuit of fig. 15 , where two sine waves are applied to the two channels and Oscilloscope is kept in X-Y mode

The frequency ratio is determined by the number of loops of the pattern touching a vertical line at the edge of the pattern and the number of loops touching a horizontal line at the edge of the pattern. The reason for this is that an integral number of sine waves on the horizontal deflection plates are completed in the same time that an integral number of sine waves are completed on the vertical plates. If Tv and Th are the time periods of vertical and horizontal input sine waves respectively then

![]()

where fH and fV are the frequencies of horizontal and vertical signals respectively. In fig. 16 , lissajous figures for various frequency ratios are drawn.

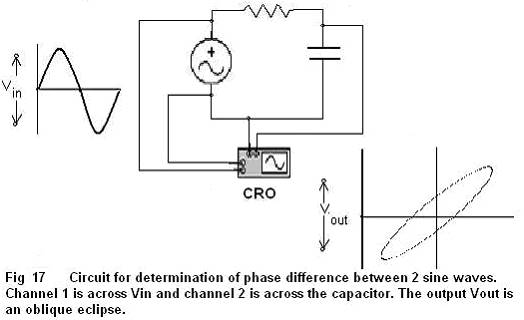

Measurement of Phase Difference

For measurement of Phase difference between 2 waves, connect the circuit as in fig. 17 .and operate the CRO in X-Y mode.

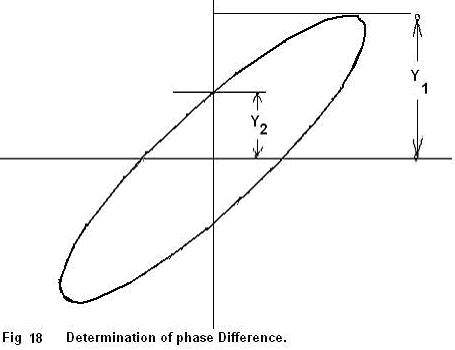

The phase difference is determined by measuring ratio of the maximum Y intercept to the intercept made on Y axis. Refer Fig 18, where Y1 is the maximum Y intercept and Y2 is the intercept on Y axis. Hence if Phase difference between the 2 waves is Φ, then

Sin Φ = Y2 / Y1. Therefore Φ = Sin-1 Y2 / Y1

Figure 19 illustrates some more patterns of lissajous figures for various values of phase differences.

References

Source: http://people.du.ac.in/~snagpal/unit1_mod_1_IN108_web.doc

Web site to visit: http://people.du.ac.in/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes