It takes a considerable time to become a skilled lathe operator, therefore it is not expected that you will be fully skilled when you have completed the machining section of this course. The models you manufacture will introduce you to basic lathe skills and open up another career opportunity. In industry people serve apprenticeships over three or four years before they are fully trained in this machine.

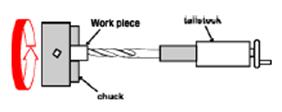

This is a diagram of an engineer's lathe. As you can see there are many components attached to this machine and it also has a large array of tools that work with it.

In this section of the course you will be identifying new tools, processes and safety requirements to ensure a high-quality model is manufactured.

The lathe has specific processes that are carried out on the machine. Below are examples of the processes you will be using when produce your models. The web links are very useful as they give excellent information on how to use the lathe and what not to do.

http://www.youtube.com/watch?v=WQKwUmXLafQ

http://www.youtube.com/watch?v=G4sRaYnnHm8

http://www.youtube.com/watch?v=Mk9vwijT7vc

http://start-model-engineering.co.uk/tutorials/lessons-on-the-lathe/

This page is very good for staff to refresh learners' knowledge. It has three 45-minute video clips.

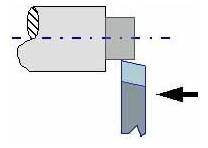

Turning down

This reduces the diameter of a rod.

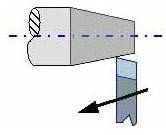

Facing off

This shortens the length of a rod and provides a smooth flat end at right angles to the side.

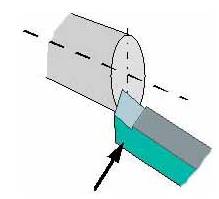

Taper turning

This process puts an angle on the rod. The top slide is used, not the cross slide. The angle can be adjusted to suit requirements.

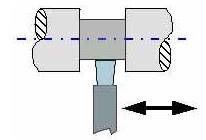

Parting off

Parting off

This is a method of cutting the length of rod. It is also used to cut right-angle grooves into the material.

Drilling

Holes drilled into the ends of rods are perfectly centred and run along the axis of the rod.

Knurling

This process places a diamond pattern on the rod. You will need to reduce the speed of the lathe. It could be used as decorative work as well as on places that need a grip (weights).

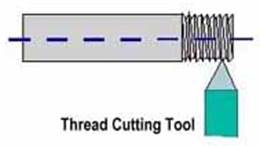

Thread cutting

This process will take time and will give a perfect thread on the rod. The lathe will need to be set up with a tool cut to the correct angle for the thread and must be sharp.

Below are pictures of some lathe tools that are available on the market. Each tool has a different use and they give a wide variety of finishes. When you are in the workshop, have a look at the tools that are set on the tool post.

You can avoid the need to grind your own tool tips by using cutters with replaceable cutting tips.

These are used to replace the carbide tips supplied with most lathes. An experienced engineer will commonly use a cutting tool that will be grinded to the required cutting profile shape and sharpened.

Tungsten-tipped tools have the end section brazed, welded or screwed on. The tungsten part cannot be re-shaped or grinded. Once these tips have been damaged or made blunt they have to be replaced.

High-speed steel (HSS), which has a hot hardness value of about 600°C, possesses good strength and shock-resistant properties. It is commonly used for single-point lathe cutting tools and multi-point cutting tools such as drills, reamers and milling cutters.

High-speed steel (HSS), which has a hot hardness value of about 600°C, possesses good strength and shock-resistant properties. It is commonly used for single-point lathe cutting tools and multi-point cutting tools such as drills, reamers and milling cutters.

Centre drill

Centre drill

The centre drill is used for starting a hole. It provides a short pilot hole for the main drill bit. It is securely attached to the tailstock in the chuck.

Twist drill

A twist drill is a drill that has deep helical grooves from the point going up the shank and is used for medal cutting.

Chuck key (with spring)

This chuck key is for an engineer's lathe and can be used in a three- or four-jaw chuck. It has a spring attached to it so that the operator of the machine can’t leave it in the chuck by mistake.

The chuck key on the left has no spring attached to it. This could be left in the machine and could cause severe injuries when its switched on.

Source: http://www.kgsorkney.com/uploads/1/4/9/3/14935550/engineer_lathe_information_sheet.doc

Web site to visit: http://www.kgsorkney.com

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes