Beating down is a forming process in art metalwork where the centre of a piece of metal is stretched to form the bottom of the object. This method of forming is generally used for shallow forming operations. Examples of projects that are formed by beating down are nut dishes, candy dishes, ash trays and plates.

Two methods of beating down art metals are with form blocks, and over stakes.

The easiest way to beat down metal is with form blocks, Figure 2. If the item is needed in small quantity wooden form blocks are used. If the item is needed in a large quantity metal form blocks are more durable. Wooden form blocks are usually made from close-grained hardwood such as maple or birch. Choose stock free of defects and use abrasives so the surfaces of the form are smooth. When making irregular shaped form blocks like the one in Figure 2, you can use a band saw and saw the pattern from 1 inch stock. Glue this to another piece of flat 1 inch stock. Another method is to use gouges, and hollow out the desired cavity.

After making your form block, consider what kind of metal you are going to use. Is the metal soft? Is it hard to form? The size of the metal should be larger than the area of the depression in your form because some of the metal will be drawn in during the beating down process. One rule of thumb used by many art metalworkers on depressions up to 8 inch in length, is to take the longest measurement and add the depth. If your circular shape is 7 inch long and 1 inch deep, you would use metal 8 inch across. This would mean that you would have 1/2 inch of metal on each side of the depression.

Figure 2 - Irregular-Shaped Blocks for Beating down Metal can be Sawed to Shape

Figure 3 - Wooden Hammers are used when Beating down Soft Metals

Figure 4 - Silversmith and Raising Hammers are Handy for Shaping Bowls and Trays

Figure 5 - In Beating down Metal you Should Work from the Centre toward the Edge

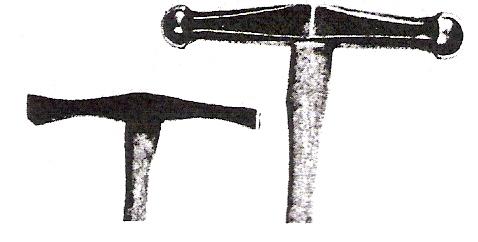

Round and rectangular shallow shapes in art metal can be beaten down over stakes of wood or metal. Figure 6 shows a stake and a wooden forming mallet made from a cracked bowling pin. The hard maple from the bowling pin is durable and does not have a prominent grain that will mark the metal.

Figure 6 - Forming Tools made from Bowling Pin

Figure 7 - Beating down over Wooden Stake

Figure 8 - Straightening Wrinkles with a Hardwood Block

Raising is a forming process in art metalwork where the sides of the metal are formed to give shape to the project. The bottom of the project can be either rounded or flattened.

This method will enable you to do deep forming operations on metal. Bowls and deep oval or circular trays are projects that can be raised.

The two common methods of forming by raising are forming over a stake, and forming over a sandbag.

Stakes are flat or rounded tools used in art metalwork for various forming, raising, bending, and planishing operations. Commercial stakes come in concave, convex, and flat shapes in a great variety of sizes. Wooden stakes are used when you do not have to have a permanent tool, or, when you need a stake with a special form. Woods that are durable for making stakes include birch, hickory, and maple. See Figure 9.

To make a wooden stake for raising, obtain suitable wood and hollow out a small circular recess about 2 inches in diameter and 3/16 inches deep. The hollowing operation can be done on a lathe, or you can use woodworking hand tools. Be sure the surface of the depressed area is sanded smooth. Figure 9 shows mallet and stakes that can be used for raising soft art metals such as pewter, zinc-based alloys, aluminium and copper. Raising hammers can also be used to shape soft metals.

Figure 9 - Metal Stakes; Wood Stake and Mallet

Figure 10 - Estimating Stock for Raising

Figure 11 - A Series of Circles Serve as Guidelines

Figure 12 - How to use a Round Stake in Removing Dents

Figure 13 - Using Stake to Remove Dents from Bowl

Figure 14 - Using Sandbag to Shape Large Project

Sandbags are used in art metalwork to form irregular shapes, and on large projects, Figure 14. A sandbag is flexible, enabling you to make a great variety of shapes.

Sandbags should not be solidly packed. This enables you to move the sand from one area to another, and shape the bag for nearly any desired contour.

Note: Decorative work involves polishing of the brass and copper items. We use polishing mops made from stitched cotton mop with Tripoli and unstitched cotton mop with rouge.

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/sheetmetal_notes/module6/Copper%20Rose%20Bowl_M6_U2.doc

Web site to visit: http://local.ecollege.ie

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes