There are many different ways of joining metal, this sheet lists the most commonly used ones.

Welding offers a permanent method of fastening and fabricating products from a wide range of materials. Welding is the joining of two materials (usually metal) in their liquid form which solidifies and fuses together to form a joint that is as strong as the parent metal.

Industrially there are many ways of achieving this fusion. Within school workshops two basic methods of welding metal are possible:

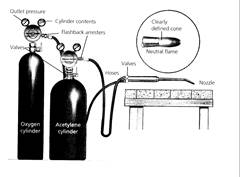

In oxy-acetylene welding a heat source of around 3500oC is produced by burning acetylene gas in oxygen. Fine adjustment to the ratio of gases is made on the hand held blowpipe. Excess oxygen gives the hottest flame, but a neutral flame, with equal amounts of gases, is the most widely used, this all depends on the thickness and type of metal being welded.

During the welding process a pool of molten metal is created. A filler rod of the same metal is dipped into this and melts filling the joint.

![]()

Fluxes are used with some materials, but not steel.

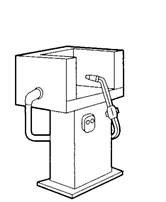

In electric arc welding an electric arc, of low voltage but high current of 10 – 120A, is struck between a metal electrode and the material to be joined.

The electrode, as well as carrying current, is a flux – coated filler rod.

![]()

Very intense heat is produced at the end of the arc, melting the electrode and the metals to be joined to form the weld bead.

The special flux gives protection from oxidation. This generates a gaseous shield, forming a molten blanket over the weld pool. As it solidifies a brittle glassy slag is formed, which can be easily chipped away when cold.

Different metal thickness require different diameters of electrode and different currents. This process is widely used because of its low capital and running costs.

To achieve an effective joint, paint, rust and any galvanised coating must be removed. The edges of thicker metal may require to be bevelled so the weld penetrates the metals and achieves high strength.

Spot welding is commercially used to give intermittent welding and some pre-tacking may be necessary with long runs.

Other types of welding are MIG & TIG.

Soft soldering is a quick method of joining most metals such as copper, brass, tinplate and steel. An exception is aluminium. The process is best confined to light fabrication where joints are not subjected to heat and vibration and so do not need to be very strong.

The surfaces must be clean before soldering is attempted. In the joining process close fitting joints are essential to ensure that the capillary action unites the surfaces. An electric soldering iron is cleaned, while hot, using a wet sponge and then “tinned” with a thin film of solder. The heat and solder should be applied together.

Brazing is a technique similar to soldering, except that considerably higher temperatures are needed. Brazing spelters is an alloy of copper and zinc (brass) and melts in the range of 870 – 880oC. This results in a much stronger joint, since brass is stronger than solder.

An air blown gas torch is needed to maintain a hot flame. This does create a limiting factor, making it too hot to use on brass and copper but it is ideal for mild steel.

Joints do benefit from interlocking, but they should all be wired or held securely to allow for expansion during heating.

Riveting is a quick and convenient method of fixing two or more pieces of material together in a permanent fashion, it is ideally suited to industrial application providing a cheap alternative to threaded fastening. The choice of rivet depends on its use.

Traditionally used with sheet metal, this method is increasingly applied to plastics and even wood.

Rivets are classified by;

Length, Diameter,

Material, Head pattern.

They are made from soft easily deformed materials such as iron, aluminium and copper.

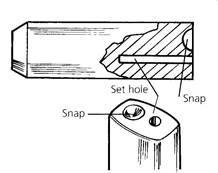

Conventional riveting employs a set and snap. The diagram below illustrates the process.

Pop rivets are quicker to use than ordinary rivets and can also be used when access is only available from one side, but they do not give as strong a joint. They consist of a hollow rivet mounted on a head pin.

In application the pin is gripped in the rivet gun and the rivet placed in a pre-drilled hole. Squeezing the gun with draws the pin.

are available in a wide range of diameters, lengths, materials, head shapes and thread forms.

![]()

Bolts

made from high tensile steel are mechanically strong, square or hexagonal headed, they are threaded for all or just part of their length.

![]()

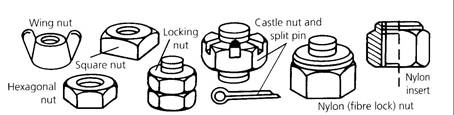

Nuts

must be matching in diameters, size and thread form to the bolt. They range from wing nuts made for easy removal to special locking nuts which resist coming loose.

![]()

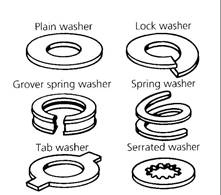

Washers

protect the surface when nuts are being heightened loosening caused by vibration.

Self Tapping screws

are suitable not only for thin sheet metal but also plastics. Made from hardened steel, they cut their own thread as they are screwed in. Preparation requires a clearance hole and a pilot hole, equal to the screw’s core diameters.

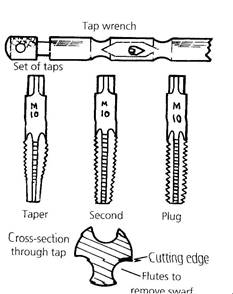

Taps and Dies

Tapping

The term ‘tapping’ is used to describe cutting an internal thread.

A set of three taps are used in sequence, with tap wrench. The taper tap makes for easier starting and in thin material may itself give a full thread.

The tapping hole must be drilled to the correct size, see the appropriate table(normally on the tap and die box). The cutting sequence involves turning clockwise half a turn and then anti-clockwise a quarter turn to break the swarf.

The tapping hole must be deeper than the required depth of the thread to accommodate any debris and the chamfered end of the plug tap.

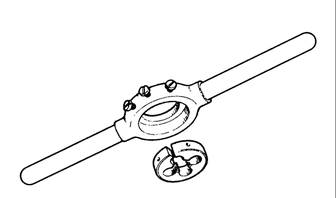

Threading

Threading describes the process of cutting the external thread.

![]()

A split die is held in a die stock.

Three screws locate and provide adjustment for the die. It fits into the stock with the size information clearly visible.

Chamfering the end of the nominal rod helps to get the thread started.

Tightening the centre screw opens the die to give a tight thread. Tightening the two outer screws will close the die making a fuller thread, but looser.

Source: http://smartdestech.weebly.com/uploads/1/2/1/9/12190579/joining_metal.doc

Web site to visit: http://smartdestech.weebly.com

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes