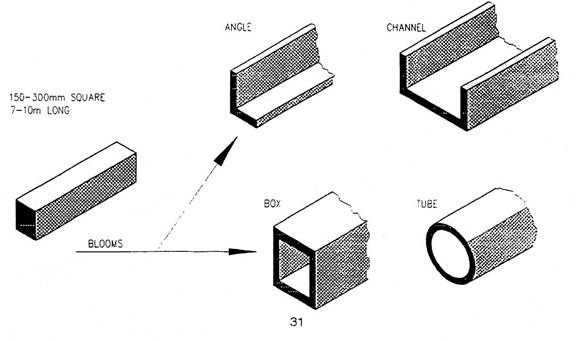

Metals are produced and supplied in many different forms, as shown in Figure 1.

Figure 1 - Different Materials/Steels available for Metal Fabrication 1

Figure 2 - Different Materials/Steels available for Metal Fabrication 2

150mm x 6mm FB (Flat Bar)

150mm x 6mm FB (Flat Bar)

100 x 6 FB

50 x 6 FB

All flat bars listed above are available in different thickness 3mm/5mm etc.

They are known as low carbon steel (LCS).

Standard sheet steel (mild steel plate) is normally available in 8ft. x 4 ft. (2500mm x 1250mm) sections 2mm/3mm, 5mm/6mm, 10mm/12mm etc.

Stainless steel and aluminium are available in the same sizes.

RSJ = Rolled Steel Joist |

|

BSUB = British Std. Universal Beam |

|

BSUC = British Std. Universal Column |

|

RSC = Rolled Steel Channel |

|

BSEA = British Std. Equal Angle |

|

BSUA = British Std. Unequal Angle |

|

RST = Rolled Steel Tees |

|

Zed Beams (Z Channel) |

|

Rolled Hollow Section |

|

Round Hollow Section |

|

Table 1 - Common Steels used in the Workshop

A ‘back mark’ is the distance from the heel of an angle or channel section to the centre of a hole in a flange.

Figure 4 - Back Marks

A ‘cross centre’ is the distance between two holes in a flange of a Universal column, beam, rolled steel joist or Tee section.

Figure 5 - Cross Centres

Figure 6 - Pocket Pad Foundation

Figure 7 - Roof Truss

This open web beam section is made by cutting the web of a hot rolled joist along a castellated line. The two halves produced are then welded together to form the section illustrated in Figure 8.

The castella beam is one and a half times the depth of the member from which it was cut, and therefore suffers less deflection under load. This section is economical for lightly loaded floors and the openings in the web are convenient for electrical and heating services.

Figure 8 - Castella Beam

When referring to beams, columns, joists and channels the depth/overall distance from flange to flange is given first followed by the breadth/width of the flange, followed by the mass per metre and finally the length required.

Figure 9 - Serial Size

Although the serial sizes are always referred to on drawings, the actual size of beams, columns etc. can vary considerably. BS41 gives dimensions for serial sizes of sections with mass per metre, actual depth and breadth and thickness of web and flange.

It will be seen that up to seven variations of a serial size is rolled and that the dimensions inside the flanges are constant, while the thickness of the web and flanges vary, hence the variation in serial size and actual size.

Figure 10 - Diagram showing production of the materials in the iron and steel group

(The production of tool steel from the Cementation process is now mainly of historical interest only.)

Figure 11 - The Basic Oxygen Furnace

Figure 12 - The Electric Arc Furnace

Figure 13 - Blast Furnace

Name |

Group |

Carbon Content % |

Some Uses |

Wrought Iron |

Wrought Iron |

Less than 0.05% |

Chain for lifting tackle, crane hooks, architectural ironwork. |

Dead Mild Steel |

Plain Carbon Steels |

0.1 to 0.15 |

Sheet for pressing out such shapes as motor-car body, panels, thin wire, rod and drawn tubes. |

Mild Steel |

0.15 to 0.3 |

General purpose, workshop bars, boiler plate, girders. |

|

Medium Carbon Steel |

0.3 to 0.5 |

Crankshafts, forgings, axles, leaf springs, cold chisels. |

|

High Carbon Steel |

0.8 to 1.0 |

Coil springs, wood chisels, files, drills, taps and dies, fine edge tools. |

|

Grey |

- |

Machine castings. |

Table 2 - Method of Production

(Note: For further information on Occupational hazards, refer to the Welder on Site…Be Aware video.)

A new Statutory Regulation concerning noise at work came into operation on July 1st, 1990.

The full title of this regulation is:

Under this regulation FAS (The Training and Employment Authority) is required to provide information to staff, trainees and apprentices on:

This section attempts to achieve this objective without going into a lot of unnecessary technical data.

If we burst a balloon, we cause a disturbance in the surrounding air which may be likened to the effect of throwing a stone in a pond. When the ripples caused by the explosion reach our ears we hear the sound of the balloon burst. It is these ripples travelling through the air that we generally regard as sound.

The human ear is sensitive to noise at frequencies or ripples between 20 times per second and 20,000 times per second. The unit of frequency is the Hertz (Hz). We then speak of the audible range as frequencies or ripples between 20 Hz and 20,000 Hz. We do not use the entire range of frequencies 20-20,000 Hz continuously. A stereo player will emit sound in a range of frequencies from 40-16,000 Hz, whereas a transistor radio covers the range 200-4,000 Hz. In normal speech the frequency range is 125-8,000 Hz but 500-3,000 Hz is the most important area. (20 Hz is a very low bass note, while 20,000 is a very high trebly note).

Loudness is the other factor that is important. We are all aware of it how quiet a whisper is and how loud a jet aircraft engine is. The loudness of a sound is measured in Decibels and this is written as dB(A). The quietest sound the average person can hear is assigned a loudness level of 0 dB(A). The loudest sound we can tolerate without pain is 120 dB(A). Table 3 gives some examples of the loudness of sounds.

Sound Loudness Level dB(A) |

Typical Environment |

|

140 |

30m from military aircraft at take-off. |

Intolerable |

130 |

Pneumatic chipping and riveting (operator’s position). |

Intolerable |

120 |

Boiler shop (maximum levels). |

Intolerable |

110 |

Automatic punch press (operator’s position) sheet metal shop – hand grinding. |

Very noisy |

100 |

Automatic lathe shop. Printing press room. |

Very noisy |

90 |

Heavy lorries at 6m. Construction site – pneumatic drilling. |

Very noisy |

80 |

Kerbside of busy street. Office with tabulating machines. |

Noisy |

70 |

Loud radio (in average domestic room). |

Noisy |

60 |

Restaurant. Department store. |

Noisy |

50 |

Conversational speech at 1m. General office. |

Quiet |

40 |

Average suburban area, whispered conversation at 2m. Residential area at night. |

Quiet |

30 |

|

|

20 |

Background in TV and recording studios. |

Very Quiet |

10 |

|

|

0 |

Normal threshold of hearing. |

Very Quiet |

Table 3 - Examples of the Loudness of Some Noises

The ear is generally considered to have three main sections, the outer, middle and inner ear (see Figure 14). The outer ear consists of the external parts of the ear canal. The middle ear comprises the ear drum and the three bones connecting it to the inner ear. The middle ear can be damaged by traumatic events such as explosion but may be surgically repaired in some cases. The inner ear converts the mechanical (ripples) world of sound to the electrical world of brain. It is the inner part of the ear, called the cochlea, which can be damaged by prolonged exposure to excessive noise.

Figure 14 - The Ear

How noise damages your hearing, when levels are too high. Excessive noise overstimulates the cochlea of the ear which translates sound frequencies into impulses which the brain can interpret. Repeated overstimulation impairs this organ and the damage cannot be repaired.

Most of us have had the experience of being temporarily deafened by exposure to loud noise, whether it is at work, or at a disco. Given a few hours rest, the ear recovers and no permanent damage is done. When exposure is continuous or repeated, however, a gradual hearing loss may result. This hearing loss is permanent and irreversible and is known as "Noise Induced Hearing Loss (NIHL)". It cannot be corrected by surgical or any other means. Even the use of a hearing aid is generally considered unsatisfactory, because of the nature of the hearing loss.

Most countries have set a limit of 90 dB(A) for continuous exposure. Ireland adapted this approach in the Noise Regulations 1975 and 1990. It is permissible to have exposures above 90 dB(A), but if so then the duration of such exposure must be limited such that the total anise dose equivalent (Leq) remains below 90 dB(A) aver 8 hours. Table 4 shows such equivalent times.

Sound Pressure dB(A) |

Allowable Exposure Time (per day) |

90 |

8 hours |

93 |

4 hours |

96 |

2 hours |

99 |

1 hour |

102 |

30 minutes |

105 |

15 minutes |

108 |

7.5 minutes |

111 |

3.75 minutes |

114 |

112 seconds |

117 |

56 seconds |

120 |

28 seconds |

123 |

14 seconds |

126 |

7 seconds |

129 |

3.5 seconds |

132 |

1.75 seconds |

135 |

Less than 1 second |

Table 4 - Noise Levels and Exposure Times

(Equivalent to 90 dB(A) for 8 hours)

Figure 15, Figure 16 and Figure 17 illustrate examples of the use of protective clothing and equipment.

Figure 15 - Protective Clothing

Name Main use

A. Flame-resistant apron Prevents burning of clothes.

B. Gas welding/cutting goggles Protects eyes from sparks.

C. Gauntlets Prevents skin burn.

D. Safety boots (steel toecap) Prevents crushing of toes.

E. Spats No molten metal down boots.

F. Boilersuit Protects neck and chest.

Figure 16 - Protective Eyewear

Name Use

A. (i) Clear glass Protects tinted lens.

A (ii) Tinted lens Limits glare.

B. Goggle body Stops sparks.

C. Air vent Prevents misting up.

D. Lens holder To change broken lens.

E. Strap adjustor Adjust for size

Figure 17 - Protective Equipment

Name Use

A. Extractor fan Takes away fumes.

B. Filter mask Dust and fumes.

C. Head shield Prevents skin burn.

D. (i) Renewable clear glass Takes spatter etc.

D. (ii) Renewable tinted Prevents arc eye.

E. Leather cape with sleeves For overhead work.

The filter mask (Figure 17B) is no protection from dangerous gases such as phosgene (which is formed from degreasing agents such as trichloroethylene) or nitrous fumes (caused when large areas of plate are heated) or any other poisonous gases. See safety precautions for TAGS and MAGS.

Note: For more information read Basic Welding and Fabrication.

Figure 18 - List all instances of unsafe practice that you can detect. (Courtesy of “What’s Wrong” Safety Posters)

Figure 19 - Body Protection

Figure 19 shows a welder fully equipped with protective clothing. The welder's body and clothing must be protected from radiation and burns caused by flying globules of molten metal. It may be necessary for a welder to wear an apron, usually of asbestos or thick leather, to protect his trunk and thighs whilst seated at a bench welding. An apron should also be worn if the welder's clothing is made of flammable material.

When deep gouging or cutting is carried out using metal-arc processes, the amount of 'spatter' is considerably greater than that experienced with normal arc welding, and therefore it is necessary to protect the feet and legs in the same way as the hands and forearms. Suitable leather leggings and spats are available and should be used to prevent burns to the legs, feet, and ankles.

Note: For more information read Fundamentals of Fabrication and Welding Engineering.

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/metalfab_notes/Introduction%20to%20the%20Metal%20Fabrication%20Trade_M1_U1.doc

Web site to visit: http://local.ecollege.ie/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes