Polystyrene thermal insulation is rigid, cellular foam insulation. It is commonly classified as either “Expanded Polystyrene Foam (EPS)” or “Extruded Polystyrene Foam (XPS)”.

Expanded polystyrene grains are heated by steam, which causes them to expand. They are then conditioned and, as they cool, the steam in the voids within the board condenses, thus permitting air to diffuse into them. After conditioning, the granules can be cast into moulds and further expanded using blown steam. The granules tend to fuse together, forming rigid blocks. The blocks are then cut to shape depending on the customer’s requirements. The material has similar characteristics to polyurethane with excellent resistance to moisture with a high compressive strength. The approximate maximum operating temperature is 80ºC.

This is produced by a continuous extrusion process based on the steam injection process. This results in a continuous product with a smooth-surface skin and enhances the mechanical properties.

Polystyrene is an excellent insulator. It is light in weight, clean and easy to handle and is cost effective. Not only has it the capability to insulate against noise and extreme temperature but it is also waterproof and long lasting. The combination of these qualities makes polystyrene an exceptionally useful product. The normal density range is 15 to 35 Kg/m³.

Polystyrene is used within the packaging industry as a high packaging solution to protect a large range of products from damage during transport and storage.

It is used in industrial insulation for insulation on pipe work, equipment, tanks, and ducts operating at temperatures below ambient. These include food and beverage lines, and refrigeration lines. Polystyrene is also used in construction for ceiling tiles, wall insulation and floor thermal insulation.

Expanded polystyrene is generally white in color and is mainly available in 2.4mt x 1.2mt sheets. Extruded polystyrene is available in pre-formed slabs and sheets and pre-formed pipe sections. Sheets are typically available in 2.4mt x 1.2mt or 2.4mt x .6mt.

The thickness of polystyrene varies depending on the application. Sheets of polystyrene for wall and floor insulation vary from 12mm to 50mm thick and larger thicknesses are available on request. He normal density rang of polystyrene is between 15 to 35 Kg/m³.

The approximate maximum continuous operating temperature is 80ºC.

Expanded polystyrene foams are flammable, although fire-retardant grades are available.

Phenolic insulation is rigid foam insulation with a closed cell structure. The exceptionally high level of closed cells and the fine cell structure gives phenolic foam exceptional thermal properties. Closed cell phenolic foams are the most thermally efficient insulation materials commonly available. The product is manufactured in a number of forms including blocks, continuously produced flexible faced laminate, rigid faced laminates and composite panels in addition to highly specialised applications such as fire doors and moulded products. Being based on phenolic resin it has outstanding fire characteristics and extremely low smoke emission when exposed to a flame source.

The exceptionally low thermal conductivity of closed cell phenolic foam boards means that appropriate insulation efficiency can be achieved with the thinnest possible material. This can be a significant advantage in building regulations, for example, in plaster board dry wall lining systems where internal room space is maximised and in cavity wall applications where the building envelope thickness is minimised.

It has excellent moisture resistance as a result of low water vapour permeability and 90% closed cell structure. It is also non-fibrous which is particularly relevant for use in hospitals, food preparation areas and breweries.

Phenolic foam is also used extensively in industrial heating and ventilation applications such as pipe equipment, tanks and duct insulation. It is also used in building applications such as roofing, flooring, cavity walls and in the food processing industry for steel faced panels.

Phenolic foam is available in pipe sections, blocks, rolls and slabs.

Cut pipe sections, bends etc are available to fit all standard steel pipes up to 610mm OD and light gauge copper pipes up to 158mm OD in wall thickness up to 50mm

Phenolic foam is available from 20mm to 50mm thick.

The density range is from 35 to 200 Kg/m³ normal density.

The approximate maximum continuous operating temperature is 120ºC.

The fire performance of phenolic foam is exceptional. It combines zero or very low flame spread with negligible smoke emission and a very low level of toxic gas emission.

Polyisocyanurate (polyiso or PIR) is a closed cell, thermoset plastic rigid foam formed spontaneously when isocyanurate and polyether are mixed in the presence of a catalyst that help the molecules to rearrange and join, and a blowing agent to create the closed cells. Polyisocyanurate foam is similar in physical form to polyurethane foam but has improved dimensional stability over a wider operating temperature range, as improved insulating characteristics and fire/smoke resistance.

Compared to other forms of foam insulation, polyisocyanurate foam insulation has a higher R-value. It is lightweight, has good workability and has low thermal conductivity which means thinner insulation for any specified insulation level. The insulation performance is extremely high for the thickness of insulation. It has good mechanical properties and mechanical strength which fulfills all the requirements made of insulation materials used in the building industry. Due to its closed cell structure it does not absorb moisture.

Typical uses and applications for polyisocyanurate include roofing, walls floors and ceilings as well for use on pipelines, cryogenic applications, chilled water and low temperature steam systems.

The approximate maximum continuous operating temperature is 140ºC.

Polyisocyanurate is available in pre-formed slabs/boards, pipe sections and spray/foam in situ.

Polyisocyanurate boards can be manufactured in various thicknesses up to 200mm,

The normal bulk density is 30kg/m³ to 60 kg/m³.

Polyisocyanurate products are combustible however some products are treated with a fire retardant depending on their applications.

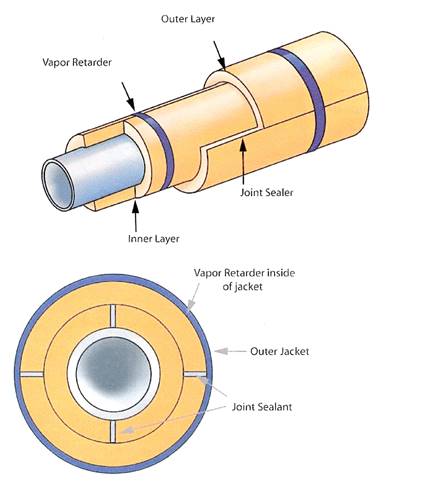

A vapour barrier must be used over the insulation on all plant operating at temperatures below the ambient air. The vapour barrier should be applied such that it is continuous and gives protection to the whole surface of the insulation which it covers. It should not be pierced or otherwise damaged. Means of load distribution must be provided at points of support as necessary. He material selected for use s a vapour barrier must be compatible with the thermal insulation which it is to protect.

Typical examples of vapour barriers are:

When the operating temperature of the equipment cycles above and below the temperature of the ambient air, it will be necessary to design a vapour barrier/ breather system.

Multi-purpose adhesives and sealants are available for bonding of hard insulating foams like polystyrene, phenolic and polyisocyanurate. Adhesives are available in an aerosol can, container or bulk form. When the adhesive is fully dried, it is designed to provide strength greater than the internal strength of most polystyrene foams.

Insulation finishes are applied over the insulation to provide a vapour barrier, weather protection, protection from mechanical damage and improved aesthetics. Some finishes would include:

Refer to Module 4 – Unit 15 – Finishing materials and cladding.

Gloves should be worn when handling insulation products. The foam insulation is easily cut using a trimming knife or hand saw. When working in elevated positions or in strong winds care should be taken that the insulation panels are not blown away. When cutting, avoid dust generation, wear a dust mask to eliminate inhaling the dust particles. Eye protection should be worn if cutting the insulation with a mechanical saw.

Waste material should be disposed of correctly and in accordance with local authority regulations. Dispose of waste materials regularly to avoid possible ignition or wind dispersal. Ensure polythene packaging is kept away from children.

Polystyrene, Phenolic foam and Polyisocyanurate foam insulations are lightweight, have good thermal efficiency, flexible and are water resistant. These foam insulations are used considerably in the industrial insulation industry for insulating ventilation systems, air-conditioning systems, pipe systems, tanks and vessels. They are also used considerably in the building industry for insulating floors, cavities and ceilings.

These products are available in slabs, boards, pipe sections and pre-formed sections. Their maximum operating temperature range is between 80ºC for polystyrene and 140ºC for polyisocyanurate with the maximum operating temperature of phenolic foam at 120ºC. They can be manufactured with a fire retardant to reduce their combustability.

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/ind_insulation/mod4/m4_u11.doc

Web site to visit: http://local.ecollege.ie/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes