Taps are used for cutting internal threads, such as the thread on a nut. This is called tapping. There are three kinds: taper tap, second or intermediate tap and plug or bottoming tap.

Figure 2 – Taps

Taper tap: This is tapered over the first 8 to 10 threads, allowing it to enter the hole and gradually cut to the full thread depth.

Second tap: This is tapered over the first four threads or so, and is used after the taper tap when tapping a deep hole or a blind hole.

Plug tap: This has only a short taper, one or two threads. It is used for finishing the thread at the bottom of a deep or a blind hole.

Taps are made from high-speed steel. They are hard and brittle and must be used with care to avoid breaking them, especially the smaller ones. The flutes along the body provide the cutting edges, also spaces for the chips being cut, and passageways for the cutting fluid to reach the cutting edges. The ends are square for gripping in a tap wrench. Taps should always be cleaned after use.

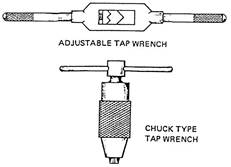

A tap wrench is used to rotate taps. There are two types shown in Figure 3.

Figure 3 - Tap Wrenches

When mating parts are being threaded, the tapping should be done first. The reason for this is that the size of the tap is fixed, but the die for cutting an external thread can be adjusted slightly, so that the thread on the bar can be progressively deepened until it just fits the tapped hole.

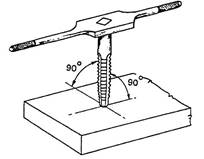

Figure 4 – Tapping

Before tapping, a 'tapping size' hole is drilled. This is smaller than the size of the tap. The drill size can be got from a table. If a table is not available, it may be got by trying the taper tap in the drill gauge until the hole is found into which it fits to a depth of three threads. Another method is to select the drill which just passes through a nut with the same size and type of thread.

To tap the hole, grip the taper tap in the tap wrench and enter it in the hole. Apply a slight downward pressure, keeping the tap in line with the hole, and turn it clockwise until it starts to cut. When it has just gripped, check if it is square with the face of the work. Correct, if necessary, and apply a cutting fluid, unless tapping cast iron or brass. Rotate the tap clockwise again for about half a turn, and then reverse it about a quarter of a turn to break off the chips. Continue in this manner, gradually screwing the tap into the hole.

If the hole is all the way through and the material is thin, the thread can be finished with the taper tap. If the material is thick, the second tap must be used after the taper tap, and sometimes the plug tap, depending on the depth of the hole. The second and plug taps must be also reversed about every half turn, to

break off chips

.

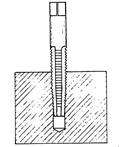

Figure 5 - Tapping a Blind Hole

A blind hole cannot be threaded at its bottom with a taper tap. Therefore, the second and plug taps must also be used. The taper tap is used first, and then the second tap and finally the plug tap to finish the thread to the bottom. During the tapping, the tap must be withdrawn from time to time to remove swarf from the hole and from the tap flutes. Care must be taken to avoid breaking the tap by forcing it against the bottom of the hole. If the blind hole is shallow, it may not be possible to start the thread with the taper tap. It should therefore be drilled deeper than the required length of thread, if possible. If not; it may be started with the second tap, but special care must be taken.

Examples of common tapping faults and their possible causes are given in the table below:

Fault |

Causes |

Broken tap |

|

Shallow thread |

Tapping hole too big. |

Stripped thread |

|

Rough thread |

|

Bolt not square with work face |

Hole not drilled square with work face. |

Table 2 - Common Tapping Faults

Figure 6 - Tapping a Through Hole

Stocks and dies are used for cutting external threads on round bars and on pipes. This is called screwing. The dies are made from high carbon steel or from high-speed steel. They are held in stocks to rotate them.

Figure 7 - Stocks and Dies

There are different forms of stocks and dies avai1able. Circular split dies are the ones mostly used in school workshops. The split permits a small amount of opening and closing of the die. The point of the central adjusting screw in the stock fits into the split in the die. To open the die, the screws at either side are slackened off and the centre one tightened. After adjusting, the side screws are retightened to lock the die in the stock. To close the die, the centre screw is slackened off and the side screws tightened. The first two or three threads on one side of the die are chamfered to make starting easier.

Before fitting the die, the stock recess must be thoroughly cleaned out to allow the die to seat properly. When fitted, the die chamfer must be on the underside and the stock retaining shoulder on top.

The end of the bar should be chamfered to help start the die. If using a circular split die, it should be opened fully to take a light first cut.

Place the die on the end of the bar with its chamfered side down. Rotate the die, keeping it square with the bar, and apply downward pressure until it begins to cut. Check for squareness and correct if necessary. Continue rotating, reversing after about each full revolution, to break off the chips. Apply cutting fluid as for tapping.

When the required length is reached, remove the die by turning it in the opposite direction. Clean the thread and try a nut on it, or try it in a tapped hole. If too tight, close the die slightly and take another cut, as before. The deepening of the thread must continue until the nut can be just screwed on by hand without any slackness.

After grinding the chamfer on the edge of the material the sequence for cutting the thread is shown in the following diagrams.

Figure 8 - Sequence of Cutting a Thread

Fault |

Causes |

Broken die teeth |

|

Stripped thread |

|

'Drunken' thread (Bar going from side to side as it is screwed into tapped hole). |

Not starting die square with bar. |

Difficulty in starting die square. |

Uneven chamfer on bar. Broken teeth on starting side of die. |

Rough threads |

|

Bar end twisted off. |

Over-size bar. Cut too heavy |

Table 3 - Faults Which May Occur When Screwing

Figure 9 - Screw Thread Terminology

Nom. Dia. Tap m/m |

Pitch m/m |

Tapping Drill |

Nom. Dia. Tap m/m |

Pitch m/m |

Tapping Drill |

2.0 |

0.40 |

1.65 or 1.60 m/m |

14.0 |

1.50 |

12.50 or 12.60 m/m |

2.2 |

0.45 |

1.80 or 1.75 m/m |

14.2 |

1.25 |

12.80 or 12.90 m/m |

2.5 |

0.45 |

2.10 or 2.05 m/m |

16.0 |

2.00 |

14.00 m/m |

3.0 |

0.50 |

2.55 or 2.50 m/m |

16.0 |

1.50 |

14.50 or 14.60 m/m |

3.5 |

0.60 |

2.95 or 2.90 m/m |

18.0 |

2.50 |

15.50 or 39/64" |

4.0 |

0.70 |

3.30 m/m |

18.0 |

1.50 |

16.50 m/m |

5.0 |

0.80 |

4.20 m/m |

20.0 |

2.50 |

17.50 or 11/16" |

5.0 |

0.50 |

4.50 m/m |

20.0 |

1.50 |

18.50 m/m |

6.0 |

1.00 |

5.10 or 5.00 m/m |

22.0 |

2.50 |

19.50 or 19.75 m/m |

6.0 |

0.75 |

5.20 or 5.30 m/m |

24.0 |

3.00 |

21.00 or 21.25 m/m |

7.0 |

1.00 |

6.10 or 6.00 m/m |

27.0 |

3.00 |

24.00 or 24.25 m/m |

8.0 |

1.25 |

6.90 or 6.80 m/m |

30.0 |

3.50 |

26.50 or 1.3/64" |

8.0 |

1.00 |

7.00 or 7.10 m/m |

33.0 |

3.50 |

29.50 or 1.5/32" |

9.0 |

1.25 |

7.90 or 7.80 m/m |

36.0 |

4.00 |

32.00 or 1.1/4" |

10.0 |

1.50 |

8.60 or 8.50 m/m |

39.0 |

4.00 |

35.00 or 1.3/8" |

10.0 |

1.25 |

8.80 or 8.90 m/m |

42.0 |

4.50 |

1.31/64" or 37.50 m/m |

10.0 |

1.00 |

9.00 or 9.10 m/m |

45.0 |

4.50 |

1.39/64" or 40.50 m/m |

11.0 |

1.50 |

9.60 or 9.50 m/m |

48.0 |

5.00 |

1.45/64" or 43.00 m/m |

12.0 |

1.75 |

10.40 or 10.20 m/m |

52.0 |

5.00 |

1.55/64" or 47.00 m/m |

12.0 |

1.50 |

10.50 or 10.60 m/m |

56.0 |

5.50 |

2" or 50.50 m/m |

14.0 |

2.00 |

12.20 or 12.00 m/m |

60.0 |

5.50 |

2.5/32" |

Table 4 - Tapping Drill Sizes for ISO Metric Threads

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/pipefitting/word/m1_u4.doc

Web site to visit: http://local.ecollege.ie

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes