* Low vacuum (no baking).

* High vacuum (baking up to 200°c).

* Ultra-high vacuum (baking up to 400°c).

Materials and design depends on the vacuum range

For use at low and high vacuum system.

Usage:

Cleaning: only wiping with dry cloth.

Lubrication – avoided in good designs. If necessary – only very small amounts of good vacuum grease

(Silicone, Apiezon L, M, N, T; Apiezon W – already solids)

Surface preparation: Turning machine, no sand paper or brush - the surface should be free from radial scratches.

Trapezoidal groove.

Old style design, technologically difficult. Dead volume problem (gas trapped in the dead volume deteriorating the vacuum). O’ ring compression ratio 33%.

Old standard design. O`ring compression ratio 33%

Rectangular grooves and holders.

O’ ring compression ratio 22%.

O’ ring compression ratio 22%.

Similar design for rods and shafts:

Standards: Kwik-Flange (US standards KF-XX , Leybold joint,

Standards: Kwik-Flange (US standards KF-XX , Leybold joint,

Quick flange , “Fast seal” etc. European NW-XX

e.g., NW-32 means that the clearance of the tube (i.d.) is 32mm.

e.g., NW-32 means that the clearance of the tube (i.d.) is 32mm.

Standards ISO

Flanges and joints Fig 10 (for sizes Fig 11a).

Available - rotated and permanent flanges. Fig 11

Co-seal - Eduards

Routable flanges and permanent joints

Metal O`ring seals – Cu and Au

CF (Conflat Flange) components, see Fig 12-13. The standard based on Cu gaskets and flanges with the cutting fringes. (Del-Seal – US commercial name for the same standard)

The operating principle: mates with identical recessed knife-shaped edges. Flanges are bolted together with a copper gasket between the cutting fringes. The fringes press annular grooves in each side of the gasket material creating extremely high pressure, filling all voids and defects, and producing a leak-tight seal.

Lateral grooves: serve for outgasing and releasing vapours during the baking procedures.

Big chambers which are frequently opened - viton seal or metal (gold) o`ring.

Isolation valves.

operated manually, electrically, or pneumatically.

Gate valves.

Gate valves.

Its purpose is to leave a wide unobstructed bore between two parts of the vacuum system and provide a high conductance path. The most frequent application is in separation of the chamber from the high vacuum pumps. Secondary application include e.g., ports for sample transfer from one section to another, transferring UV radiation in synchrotron experiment, or transferring a particle beam in accelerator experiment.

Because of possible large pressure deference on both sides of a valve, large gate valves should to be assisted by a by-pass valve

Design as:.

These simple valves open to give a high conductance but obstructed path. As the flapper remains in the valves bore. They are used above diffusion pumps and in forelines. When mounting this type of valve remember to leave room above and below for the flapper to rotate. See

These simple valves open to give a high conductance but obstructed path. As the flapper remains in the valves bore. They are used above diffusion pumps and in forelines. When mounting this type of valve remember to leave room above and below for the flapper to rotate. See

Variable conductance valve. The variable Q valve provide high conductance during initial pumpdown of a vacuum chamber and then give controllable differential pressure between pump and chamber during sputtering, etching and other gas processes. By limiting the throughput of gas to the pumps, conductance controller conserves gas usage, prevent pumps overload, and generate optimum flow rates for the process. See Fig 15b.

Needle valves.

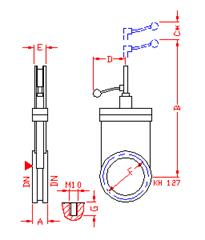

For precise regulation of the gas flow, i.e., for controlled gas admission. The needle valve should not be used to close the gas line in the system - it has to be backuped by a regular cut-off valve. Fig 16.

UHV valves - All metal beakeable valve.

Liquids, gas, liguid nitrogen

e.g. cooling water for devices in vacuum

Lq. N2: Do not use standard tube coupling to transfer LN2 into a vacuum system - the O-ring will freeze – remember the Challenger disaster!

LN2 feedthroughs are design to limit the heat flow from the flange to the feedthrough tube

Electrical feedthroughs

The name instrument feedthrough is given to any electrical feedthrough specifically designed to transfer signals, usually low in voltage and current. These feedthrough terminate in a standard plug or socket on the atmospheric side and are supplied with a mating part for cable attachment. There are tow types of instrumentation feedthroughs: coaxial and multi-pin. The consideration in choosing instrumentation feedthrough :

This group has one or many conductor that penetrates the vacuum wall. Each conductor is vacuum-sealed by bonding to the surrounding flange via an electrical insulator. The insulator can be anything compatible with the vacuum and temperature requirements. Most manufacturers use alumina ceramics spacers, UHV-compatible, and can be baked at 450°C.

The conductors must be build from the same metal, or an acceptable compensating metal, as the TC. Consideration in selecting the TC feedthrough:

The temperature range.

The temperature range. Note: not all T.C. materials are available in the vacuum feedthrough form.

Note: not all T.C. materials are available in the vacuum feedthrough form.

Mechanical motion feedthroughs.:

Mechanical motion feedthroughs.:

Optical feedthrough.

The most commonly used material for vacuum chambers and associated component is stainless steel. Elements are welded using an argon arch-welding. The most frequently used steel materials are grades 304, 316, and 316LN (in that order). Low gas permeability, resistance to corrosion and ability to take high polish make these stainless steels desirable vacuum material.

For large vacuum chambers expected to work in the 10-6 Tr range mild steel is often chosen for its lower price. Magnetic, corrosion and outguessing properties make it an unlikely choice for normal-scale vacuum chambers.

Glass is a common chamber material in educational and some research laboratories

Blanks, screws, nuts, wires, grease, etc.

Rule of the game:eliminate dead volumes – hollow screws!

Source: http://physweb.bgu.ac.il/COURSES/ExperiMethods/lecture_notes/1_4_Vacuum_equipment_and.doc

Web site to visit: http://physweb.bgu.ac.il/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes