Electric Shock: Physiological effect resulting from an electric current passing through a human or animal body ( see also shock current ).

Shock Current: A current passing through the body of a person or animal and having characteristics likely to cause physiological effects.

Danger: Risk to health, life or limb from shock, burn, or injury from mechanical movement of electrically driven equipment or from fire, attendant upon the use of electrical energy.

Flammable: Capable of being easily ignited.

Basic Insulation: Insulation applied to live parts to provide basic protection against electric shock.

Note 1: Basic insulation will normally need supplementary measures in order to complete the protection against electrical shock.

Double Insulation: Insulation comprising both basic safety insulation and supplementary insulation.

Note: See also Class II equipment

Reinforced Insulation: A single insulation system applied to live parts, which provides the same degree of protection against electric shock as double insulation.

Earth: The conductive mass of the earth, the electric potential of which at any point is conventionally taken as equal to zero.

Conductive Part: A part capable of conducting current but not necessarily used for carrying service current.

Exposed Conductive Part: A conductive part of electrical equipment, which can be touched and is not normally live but may become live under fault conditions.

Note: A conductive part of electrical equipment, which can only become live under fault conditions through an exposed conductive part, is not considered to be an exposed conductive part for the purposes of the se Rules.

Extraneous Conductive Part: A conductive part, not forming part of the electrical installation, liable to introduce a potential, generally the earth potential.

Note: Examples are:

Fault: Contact of a live part with exposed or extraneous conductive parts, which is caused by accident or failure of insulation.

Fault Current: A current resulting from an insulation failure or the bridging of insulation.

Protective Conductor ( symbol PE ): A conductor required for certain measures of protection against electric shock, which electrically connects any of the following parts:

Earth-Fault Current: A fault current that flows to earth either directly or through a protective conductor.

Earth Leakage: ( see Leakage Current )

Leakage Current ( in an installation ): A current that flows to earth or to extraneous conductive parts in an electrically undamaged circuit.

Note: This current may have a capacitive component including that resulting from the deliberate use of capacitors.

Arm’s Reach: A zone extending from any point on a surface where persons usually stand or move about, to the limits, which a person can reach with the hand in any direction without assistance.

Simultaneously Accessible Parts: Conductors or conductive parts that can be touched simultaneously by a person or, where applicable, by livestock.

Note: Simultaneously accessible parts may be:

Touch Voltage: Voltage appearing between simultaneously accessible parts, during an insulation fault.

Note 1: By convention, this term is used only in connection with protection against indirect contact.

Note 2: In certain cases, the values of the touch voltage may be appreciably influenced by the impedance of the person in contact with these parts.

Direct Contact: Contact of persons or livestock with live parts.

Barrier: A part providing protection against direct contact from any usual direction of access.

Obstacle: A part preventing unintentional direct contact, but not preventing direct contact by deliberate action.

Indirect Contact: Contact of persons or livestock with exposed conductive parts or extraneous conductive parts, which have become live under fault conditions.

Class I Equipment: Equipment having basic insulation throughout, and depending on the earthing of exposed conductive parts for protection against indirect contact in the event of failure of the basic insulation.

Class II Equipment: Equipment having double insulation or reinforced insulation, or a combination of these throughout, and whose intermediate parts are protected by supplementary insulation so that there is no risk of indirect contact in the event of failure of basic insulation.

Note: Class II equipment is marked with the symbol shown in Figure 1.

|

Figure 1.

Supplementary Insulation: Independent insulation provided in addition to the basic safety insulation in order to ensure protection against electric shock in the event of failure of the basic safety insulation ( usually associated with Class II equipment ).

Design Current ( of a circuit ): The current intended to be carried by a circuit in normal service.

Rated Current ( of a circuit ): The maximum value of current for which the circuit is intended.

Current Carrying Capacity ( CCC ) (of a conductor ): The maximum current that can be carried continuously by a conductor under specified conditions without its steady-state temperature exceeding a specified value.

Fuse: A device that, by the fusing of one or more of its specifically designed and proportioned components, opens the circuit in which it is inserted by breaking the current when this exceeds a given value for a sufficient time. The fuse comprises all the parts that form the complete device.

Rated Current ( of a protective device ): The value of current for which the operating conditions of the protective device are determined.

Note: For adjustable protective devices, the current setting is considered to be rated current.

Fusing Current: The minimum value of current flowing through a fuse, which will cause the fuse to interrupt that current in stated conditions.

Overcurrent: Any current exceeding the rated value. For conductors, the rated value is the current-carrying capacity.

Overload Current ( of a circuit ): An overcurrent occurring in a circuit in the absence of an electrical fault.

Short Circuit Current: An over-current resulting from a fault of negligible impedance between live conductors having a difference in potential under normal operating conditions.

Prospective Short Circuit Current : The value of short-circuit current that would flow if the current-limiting device were replaced by a conductor of negligible impedance.

Breaking Capacity: A value of current that a protective device is capable of breaking at a specified voltage and under prescribed conditions of use and operation.

Switch (mechanical): A mechanical switching device capable of making, carrying and breaking currents under normal circuit conditions, which may include specified operating overload conditions and also carrying for a specified time currents under specified abnormal circuit conditions, such as those of a short-circuit.

Circuit Breaker: A mechanical device capable of making, carrying and breaking currents under normal circuit conditions and also capable of making, carrying for a specified time, and breaking currents under specified abnormal circuit conditions, such as those of short circuit.

Residual Current: The algebraic sum of the instantaneous values of current flowing through all live conductors of a circuit at a point.

Residual Current Device

( RCD ): A mechanical switching device intended to disconnect a circuit when the residual current attains a stated value under specific conditions.

Residual Current-Operated Circuit-Breaker

( RCCB ): A mechanical switching device designed to make, carry and break currents under normal service conditions and to cause the opening of the contacts when the residual current attains a stated value under specified conditions.

Residual Current-Operated Circuit-Breaker with Integral Overcurrent Protection

( RCBO ): A residual current-operated circuit-breaker designed to perform the functions of protection against overloads and / or short-circuits.

Residual Operating Current: Residual current value that causes the residual current device to operate under specified conditions. ( Values range from 10mA to 500mA ).

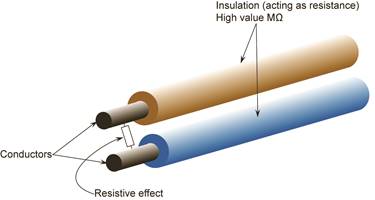

Live conductors are separated from each other and from earth by insulation. This insulation ensures that the current flowing between conductors and to earth is kept to an acceptably low level. In simple terms, insulation is perfect, so that its resistance is infinite and there is no current flow through it at all. In practice however, there will always be a very low current, flowing between conductors and to earth. This is known as Leakage Current. This current is made up of three components.

The insulation between conductors at different voltages, behaves as the dielectric of a capacitor. The conductors behave as the capacitor plates. When a direct voltage is applied to the conductors, charging current will flow. It will quickly die away as the effective capacitor becomes charged ( usually in much less than one second ). When an alternating voltage is applied, there will be charging and discharging taking place. There will be a continuous flow of alternating current through the insulation.

Figure 2

The resistance of the insulation is not infinite, so a small current flows through its resistance. If the insulation is damaged ( bruised, cracked or damaged by heat ) this current value will increase.

Where the insulation is removed for connection of conductors and so on, current will flow across the surfaces between the bare conductors. If the surfaces are clean and dry, the value of the leakage current will be very small indeed, but it may become significant in wet and dirty conditions.

The total leakage current is effectively the sum of the capacitive, conduction and surface leakage currents described above. Each current, and hence the total leakage current is affected by factors such as ambient temperature, conductor temperature, humidity and the value of voltage applied.

Insulation resistances are all effectively connected in parallel. The total insulation resistance will therefore be lower than that of each individual circuit. In a large electrical installation, the total insulation resistance may be lower than that of a smaller installation.

An electric shock is the passage of an electric current through the body. The amount of current which is lethal varies from person to person, and also depends on the parts of the body through which it flows. To understand why we are ‘shocked’, we must realise that every movement we make, conscious or unconscious, is produced by muscles reacting to minute electric currents generated in the brain. These currents are distributed to the correct muscles by the ‘conductors’ of the nervous system.

If a current much larger than the one usually carried is forced through the nervous system, the muscles react much more violently than normal, and hence we experience the ‘kick’ associated with an electric shock. If in addition, the nerves carry the excess current to the brain, it may destroy or cause temporary paralysis of the cells which generate the normal currents. Destruction of these cells means almost instant death, as the heart muscles cease to operate and no blood is circulated. Paralysis results in unconsciousness, but if the lung muscles are not operating, death from suffocation will follow in a few minutes.

The severity of shock depends on the amount of current flowing through the body, the path it takes and the time for which it flows. The amount of current flowing increases as the applied voltage increases, and decreases as circuit resistance increases. Thus, in identical circumstances, a worse shock will be received from a high voltage than from a low voltage.

Many circuits such as those associated with bells and telephones are operated at extra low voltage and so the risk of shock is removed. High voltage shocks are often accompanied by severe burns.

For a given voltage, the severity of the shock received will depend on the circuit resistance. This is made up of the following:

Contact with the general mass of earth: The body is normally separated from the conducting mass of earth by one or more layers of insulating material, i.e. shoes, floor coverings, floors, etc. It is the resistance of these insulators which normally prevents a shock from being serious. For instance, a man wearing rubber-soled shoes standing on a thick carpet over a dry wooden floor can touch a live conductor and feel nothing more than a slight tingle. The same man standing on a wet concrete floor in his bare feet would probably not live to describe his sensations on touching it. Depending on whether the body is dry, moist, or wet, the value of resistance measured between hands, or between hands and feet, can be anywhere between 1000W and 10,000W. As we have seen from Ohms law, the current flowing through a body will depend on the voltage across it and the resistance of the body. Different levels of current will have different effects, the worst occurring when the heart goes out of rhythm and will not return to normal. This condition is known as ventricular fibrillation and will often result in death. Below is a guide to the various levels of shock current and their effects on the body.

Current ( mA ) Effect

1-2 Perception level, no harmful effects

5 Throw-off level, painful sensation

10-15 Muscular contraction begins, cannot let go

20-30 Impaired breathing

50 and above Ventricular fibrillation and death

It will be seen that 50 mA ( 0.05 A ) is considered to be the minimum lethal level of shock current, and so, if a persons body resistance is as low as 1000 Ohms, the voltage required to cause this current to flow is:

U = I x R

I = 50 mA = 50 x 10-3 Amps

R = 1000 Ohms

U = 50 x 10-3 x 1000

U = 50V

Voltage levels up to 50 Volts are considered to be safe and are referred to as Extra Low Voltage ( ELV ).

The following is an introduction to earthing, the topic will be dealt with in more detail in the Course Notes for Unit 2.2.6. The general mass of earth is made up almost entirely of materials which are reasonable electrical conductors, or become so when moist.The general mass of the earth is considered to be at zero potential and is defined as follows: “The conductive mass of the earth, the electric potential of which at any point is conventionally taken as equal to zero.”

In practice, the neutral at the supply mains is almost always connected to the general mass of the earth. This is done by connecting a conductor from the neutral at the supply origin to earth. See Figure 5.

This means that a person touching a live part of an installation, whilst standing on the earth, would suffer a severe electric shock. Remember that the accepted lethal level of shock current passing through a person is only 50 mA. Similarly, an electric shock would occur if the person were touching a faulty appliance and an earthed metallic gas or water pipe.

One method of providing some measure of protection against these effects is to connect together ( bond ) all metallic parts of an installation and connect them to earth. See Figure 6. This ensures that all metalwork is at zero potential. As a result under fault conditions this metalwork will remain at or near the same potential. Simultaneous contact with two such metal parts would not result in a shock being received.

.

When a phase to earth fault occurs on an appliance, a current can flow via the earthed metalwork, back to the supply neutral, as shown in Figure 7.

These currents are referred to as “earth leakage currents” or “earth fault currents”.

Earth Leakage Currents

Insulation is not perfect. Earth leakage current of perhaps no more than a few milliamps can flow through the insulation on items of electrical equipment, cables etc. These currents are “normal earth leakage currents”. They cause no problems;

For example: 5 mA flowing through the insulation of an electric kettle element.

If the insulation deteriorates this current will increase to an unacceptable level.

For example: 30 mA flowing through the insulation of an electric kettle element.

Should this occur the supply must be disconnected from the item.

Leakage currents of approximately 300 mA are capable of starting a fire.

These currents can be detected and interrupted by Residual Current Devices ( RCD’s ).

Earth Fault Currents

A large current will flow to earth in the event of an earth fault. In this case a live conductor actually comes in contact with something that is connected to earth,

For example: A protective conductor or the frame of an appliance.

Earth fault currents may be in the order of hundreds or even thousands of amps. Should a fault of this nature occur, the supply must be disconnected very very quickly. Otherwise persons or animals may be electrocuted and serious damage done to electrical equipment.

All earthing and bonding conductors and connections must be capable of carrying a sustained fault current without overheating. Danger often arises from the use of inadequate conductor sizes, inadequate connections, such as a poorly made earth connection, an earth clamp which has worked loose, or corrosion of parts of the earthing system.

Earth fault currents can be detected and interrupted by fuses, circuit breakers and residual current devices.

Direct Contact

Direct contact is the contact of persons or livestock with live parts.

Electric shocks of this nature, occur when two parts of the body come into contact with conductors at different potentials.

Electric shock can be received in two ways:

Electricians may accidentally suffer electric shock or even electrocution as described in either case above.

Clearly, it is not satisfactory to have live parts accessible to touch by persons or livestock.

The ETCI Rules recommend five ways of minimising this danger, these are listed below and three of them are illustrated in Figures 10, 11 and 12.

Indirect contact is the contact of persons or livestock with exposed conductive parts or extraneous conductive parts, which have become live under fault conditions.

Electric shocks due to indirect contact can occur if a person touches the metal casing of an appliance, or extraneous metalwork, which should not normally be live, but has become live due to a fault.

Shocks from non current carrying metalwork to earth:

In the event of a break in a protective conductor, the frame of an appliance will be disconnected from earth. This fault is unlikely to be noticed until a second fault occurs from the phase conductor to the frame. The frame will become live relative to earth and this will result in an electric shock being received by a person touching the frame.

If the protective conductor is intact, and a fault occurs from the phase conductor to the frame, the frame will not become live. The fault current will flow to earth and a protective device will operate. A person touching the frame will not receive an electric shock.

Protection against electric shock by indirect contact can be achieved by one of the following methods as listed in the ETCI Rules.

1. Earthing and Automatic Disconnection of the Supply.

( This method will be dealt with later on ).

2. Provision of Supplementary Insulation ( Class 2 equipment ).

( This method will be dealt with now ).

3. Non-Conducting Location and Earth Free Local Equipotential Bonding.

( This method is not within the scope of this course ).

4. Electrical Separation.

( One aspect of this method will be dealt with later on ).

Protection by Supplementary Insulation.

This protective measure is achieved by insulating exposed conductive parts, which might become live in the event of a fault, in the basic insulation. This method of insulation is used in Class II equipment, commonly called double-insulated equipment and bearing the symbol shown in Figure 15

Double insulated equipment has no provision for a protective conductor ( PE ), even though it may have a metal casing or frame. Live parts are so well insulated, that faults to the frame cannot occur.

As well as providing protection against electric shock, electrical installations must be protected from excess current ( overcurrent ) which may damage cables and equipment or cause a fire. The term ‘overcurrent’ may be subdivided into two categories:-

Overload Currents

Electrical circuits must be designed to suit the intended load. This is known as the design current of the circuit. Overload currents are usually no more than twice or three times this design current. They occur for one of the following reasons.

The danger in all such cases is that the temperature of the conductors will increase to such an extent that the effectiveness of insulating materials will be impaired.

The devices used to detect such overload currents, and to disconnect the circuit when they occur, are the fuse and the circuit breaker.

In order to protect against overload current:

The rating of the protective device must be greater than or at least equal to the design current of the circuit.

The current carrying capacity of the cables must be greater than or at least equal to the rating of the protective device.

Short Circuit Currents

Short-circuit currents may be several hundred, or even several thousand times normal circuit current.

If a short circuit occurs the circuit protection must break the fault current rapidly, before damage is done to cables and equipment through overheating or mechanical stress. The current likely to flow under short-circuit conditions is called the prospective short-circuit current, the value of which can be measured using a special test instrument.

If the device used for overload protection is also capable of breaking the prospective short circuit current safely, it may be used for both overload and short circuit protection. In practice both fuses and circuit breakers meet these needs.

The fuse element is a cheap, useful and simple protective device. Unfortunately, it provides protection by destroying itself. After operation a fuse must be replaced, and this requires the correct replacement fuse, the use of tools, and expenditure of time. A particular fuse can never be tested without its self destruction, and the results of the test will not necessarily apply to the replacement fuse.

A fuse is the weak link in a circuit which will break when too much current flows. It protects the circuit conductors and equipment from damage. This action is referred to as the blowing, breaking or rupturing of the fuse. It must be remembered that the priority of the fuse is to protect the circuit conductors, not the appliance. Calculation of cable size therefore automatically involves the correct selection of protective devices. There are many different types, shapes and sizes of fuse available. All are designed to perform specific functions.

The fuse depends on the heating effect of an electric current for its operation. An overcurrent in the circuit results in the thermal melting of the fuse link or fuse element.

The fuse element consists of a wire of defined current carrying capacity placed in series with the circuit being protected. It will carry its rated current without overheating. When excess current flows the fuse element overheats, melts and disconnects the circuit from the supply. The term fuse refers to the whole device. The following are important terms associated with fuses.

Example: A 20 Amp fuse with a fusing factor of 1.4 will carry 20 Amps continuously and will blow when a current of 20 x 1.4 Amps, i.e 28 Amps flows.

The Cartridge Fuse

This the most common type of fuse used in this country.

Figure 16 illustrates a DZII cartridge fuse which consists of a ceramic body having two tinned brass end caps. It is filled with silica sand, and its ceramic body is both heat proof and an electrical insulator.

|

Figure 16

Figure 17 illustrates the fuse element, located inside the fuse, which carries the current required by the load on the circuit. When an excessive current flows, the element overheats and ruptures or breaks. As the element breaks, an arc occurs. Current tends to keep flowing through this arc. The silica sand extinguishes the arc and so the circuit is opened or disconnected.

|

Figure 17.

Figure 18 illustrates the indicator element which is a very thin section of fuse wire. It ruptures at the same time as the fuse element. When this occurs the small spring ejects the indicator and gives a visual indication that the fuse has ruptured or “blown”.

|

Figure 18.

Figure 19 illustrates how these parts are assembled to form the complete fuse. The fuse is shown partially filled with silica sand for clarity.

|

Figure 19.

The DZII fuse is available in the following current ratings: 2 A, 4 A, 6 A, 10 A, 16 A, 20 A and 25 A.

For ratings above 25 A, a physically larger fuse known as the DZIII fuse is used. DZIII fuses are now banned by the ETCI Rules as they have a record of overheating. However, DZIII fuses are still available for replacement purposes in current ratings of 35 A, 50 A and 63 A.

The indicator on DZ type fuses is colour coded, to enable the fuse size to be determined without having to withdraw the fuse. The opposite end, referred to as the tip, is tapered to a different dimension for each current rating.

A gauge ring of the correct size must be installed in the fuseholder, prior to installing the fuse. A gauge ring is a device which is designed to prevent a higher rated fuse being installed when a fuse has to be replaced. Gauge rings are manufactured to match the tip size and indicator colour of the DZ fuse. The following chart indicates these colours and approximate fuse tip and gauge ring sizes.

Rating (A) 2 |

Body Diameter (mm) 22 |

Gauge Ring/Tip (mm) 6 |

Guage Ring Colour + |

4 |

22 |

6 |

Brown |

6 |

22 |

6 |

Green |

10 |

22 |

8 |

Red |

16 |

22 |

10 |

Grey |

20 |

22 |

12 |

Blue |

25 |

22 |

14 |

Yellow |

Rating (A)

|

Body Diameter (mm)

|

Gauge Ring/Tip (mm)

|

Guage Ring Colour + |

35 |

27 |

16 |

Black |

50 |

27 |

18 |

White |

63 |

27 |

20 |

Copper |

A DZII fuse may be inserted into a DZIII fuse unit with the use of a ceramic fuse liner. The fuse liner centres the DZII fuse in the DZIII fuse-holder.

All DZ fuses must have the supply connected to the fuse tip for safety reasons. A gauge ring must always be used, otherwise good contact cannot be guaranteed.

The DZII fuse has been replaced by a more compact and reliable fuse known as the Neozed fuse. The Neozed fuse is available in three physical sizes covering the range 2 A to 100 A as follows:

The type of main fuse normally used in a domestic installation is the D02. It is usually rated at 63 A. Some larger domestic installations require a D03, rated at 80 A or 100 A. There is a range of adaptor sleeves available to prevent a higher rated fuse being installed accidentlly. The fuse indicators are colour coded the same as the DZII and DZIII types.

Using manufacturers time / current charts it is possible to determine how long it will take a particular fuse to “blow”, when carrying a given value of overload current.

N.B. These fuses can safely interrupt an overload current up to 80 kA. ( 80,000 Amps ).

This in other words is its breaking capacity.

Figure 20 illustrates neozed fuses,fuse cap, gauge ring and fuse liner.

The MCB ( miniature circuit breaker ) is an automatic switch which operates when excess current passes through it. The MCB can be closed again, because the device does not damage itself during normal operation. The contacts of a circuit breaker are closed against spring pressure, and held closed by a latch arrangement. A small movement of the latch will release the contacts, which open quickly under spring pressure to break the circuit. This operation can be compared to that of a mouse trap.

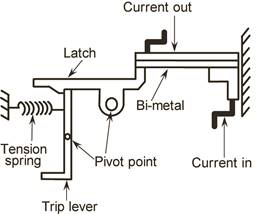

Figure 21 shows the “trip mechanism” of a MCB in the “on” or “set” position.

The circuit breaker is so arranged that normal currents will not affect the trip lever, whereas excessive currents will move it, to operate the breaker. There are two basic methods by which overcurrents can operate the trip lever.

The load current is passed through a bi-metal strip. This bi-metal strip consists of two different metals. These metals are fixed together throughout their length. The rate of expansion of the two metals is different. As the bi-metal strip heats up, it will bend towards the trip lever.

Figure 23.

The temperature of the bi-metal strip depends on the current it carries. The rated current of the MCB will not heat the bi-metal strip sufficiently to cause tripping. When an overcurrent occurs, the bi-metal strip temperature increases. After a time delay the bi-metal strip bends far enough to operate the trip lever.

Figure 24.

The time delay in the operation of a thermal device will depend on the value of the overcurrent flowing through it. The heat produced by the load current must be transferred to the bi-metal strip. Thermal tripping devices are thus best suited to low value overloads of comparatively long duration. They cannot respond fast enough to high value overloads or short circuits.

Magnetic tripping

The MCB also uses the magnetic effect of an electric current.

A coil of a suitable diameter and length of wire for the rated current of the MCB is arranged so that the circuit current flows through it. This current produces a magnetic field around the coil. This magnetic field attracts the MCB latch mechanism. The magnetic field strength will depend on the value of current flowing through the coil.

A current value of up to three times the rated current of the device must not produce a strong enough magnetic field to attract the latch. A current value in excess of three times the rated current of the device may attract the latch. A current value of five times the rated current of the device must attract the latch. These figures are for a Type B MCB. This in turn releases the trip lever, disconnecting the supply from the load.

Figure 25 illustrates the principle of operation of the Magnetic-Overload Trip.

The “set” and “tripped” positions are shown.

Set Position Tripped Position

Magnetic trips are fast acting for heavy overloads and / or short circuits, but are uncertain in operation for light overloads.

Thermal and magnetic components are thus combined in MCB’s to take advantage of their best characteristics.

Functions of an MCB

A secondary function of the MCB is that it can be used as a switch for the circuit. Consequently an MCB offers control, protection and isolation.

Advantages of an MCB

Figure 26 illustrates a general view of a Miniature Circuit Breaker

Dolly

|

Figure 26.

Types of MCB

MCB’s are manufactured in a range of types. The main types now recommended are denoted by the letters B, C and D. Other special types are denoted by the letters K and Z.

Some older types of MCB are denoted by the numerals 1,2,3 or by the letters L,G and U.

MCB’s are manufactured in such a way that they have different characteristics. Type B has a different characteristic to type C, while Type C has a different characteristic to Type D and so on.

At this stage of the Phase 2 Training Programme, we will deal with Type B, as it is the recommended type for use in domestic situations.

The Type B characteristic stipulates that the MCB must trip magnetically between 3 and 5 times its rated current, and it must trip thermally between 1.13 and 1.45 times its rated current.

Example: A 20 Amp MCB Type B will operate as follows:

Short Circuit and High Value Overload Protection ( Magnetic )

20 A x 3 = 60 Amps

20 A x 5 = 100 Amps

This 20 Amp MCB, Type B will operate between 60 and 100 Amps instantaneously.

Low Value Overload Protection ( Thermal )

20 A x 1.13 = 22.6 Amps

20 A x 1.45 = 29 Amps

This 20 Amp MCB, Type B will operate between 22.6 and 29 Amps after a time delay.

To this end, manufacture’s provide tripping characteristic graphs, which show load current on the horizontal axis and tripping time on the vertical axis. From these graphs one can check, how long it will take an MCB to trip for a given value of overcurrent.

The characteristic of a Type B MCB is such that it provides protection of cables supplying resistive loads. It is not suitable for use where switching surges are a factor e.g. starting of electric motors.

Overcurrent protective devices, ( fuses and MCB’s ), are unable to detect earth faults, below their operating currents. Where these are the only means of earth fault protection, it is possible for earth fault currents to flow, undetected, causing shock and / or fire risk. A Residual Current Device ( RCD ) will disconnect earth leakage currents, at or above its tripping current or sensitivity. This greatly reduces the shock and / or fire risk.

Residual current devices should disconnect all live conductors to the protected circuits. There are some exceptions, see ETCI Rules.

Common terms associated with RCD’s

RCCB

Residual Current-operated Circuit Breaker used in distribution boards to protect grouped or individual circuits.

RCBO

Residual Current Breaker with Overcurrent protection. This is a combined RCD / MCB and provides overload, short-circuit and earth fault protection in one unit. Supplies only one circuit.

SRCD

Socket outlet with combined RCD. These are expensive in that they only provide earth fault protection to the load connected to them. They are uneconomic for use in new or re-wire installations, as it is more efficient to protect socket circuits with one main RCD.

PRCD

Portable RCDs are available as a plugtop adaptor i.e. one unit providing a 13 A plugtop at the back end and a 13 A socket on the front. Again, they only provide earth fault protection to the load connected to them.

Current Rating ( Contact Rating )

The current an RCD can carry, make and break, without destruction to itself. e.g. 40 A. Typical Current Ratings are 13 A, 25 A, 40 A, 63 A, 80 A, 100 A. These devices require overcurrent protection, except in the case of the RCBO which has overcurrent protection built in.

Sensitivity ( Tripping Current )

This is commonly called the tripping current and is the value of earth leakage current at which the RCD will trip. The choice of sensitivity depends on the application and must be chosen in compliance with the ETCI Rules. Sensitivities are in the range 10 mA to 500 mA.

Typical Tripping Currents in common use are 30 mA, 100 mA, 300 mA, 500 mA.

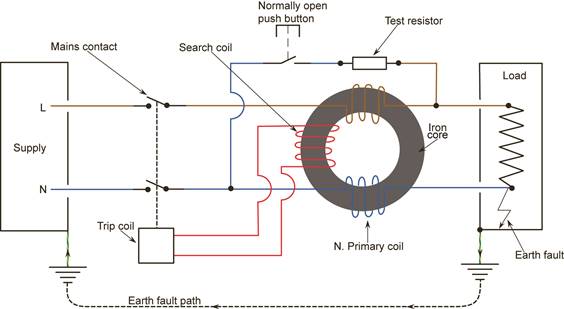

Operation of an RCD

An RCD is a device, which operates on the principle of current balance. Both phase and neutral conductors, are wound on a common transformer core forming a pair of primary coils. A secondary coil or search coil, wound on the same core is connected to a trip coil. The trip coil operates the tripping mechanism electro-mechanically. In healthy circuits the current flowing out on the phase conductor, equals the current returning on the neutral conductor. The magnetic effect of these two currents, cancel each other, therefore there is no voltage induced in the search coil.

In the event of an earth leakage fault, current will flow to earth causing an imbalance in the currents flowing through the transformer primary coils. This imbalance causes a magnetic flux to be set up in the transformer core. The magnetic flux in turn induces a voltage in the search coil, which is applied across the trip coil. The trip coil operates, the RCD tripping mechanism and the supply is disconnected from the fault on the circuit or load.

A test button is provided to allow the consumer to periodically test the mechanical operation of the RCD. It is recommended that the RCD be tested quarterly.

Figure 27 illustrates the operation of a residual current device.

Figure 27

Note: Some RCD’s contain electronic components. Where these are installed, precautions must be taken to prevent damage during an Insulation Resistance test

Types of RCD

International Standards IEC 1008 ( RCCB) and IEC 1009 ( RCBO ) divide RCD’s into two performance classes.

Type AC

RCD’s for which tripping is ensured for residual sinusoidal alternating currents, whether suddenly applied or slowly rising.

Type A

RCD’s for which tripping is ensured for residual sinusoidal alternating currents and residual pulsating direct currents whether suddenly applied or slowly rising.

Pole Configuration

SP Single Pole

DP Double pole.

TP & N Triple pole and neutral ( 4 Pole )

Voltage Rating

Single phase 230 Volts

Three phase 400 Volts

Frequency

50 Hz

Tripping Principle

Electro-mechanical

Electronic plus electro-mechanical

Terminal Capacity

The size of conductor or combination of conductors which can be properly electrically and mechanically terminated to a particular terminal e.g. ( 3 X 2.5 mm2 or 1 X 10mm2 ).

The type of switch-fuse, used in domestic type distribution boards, must accomodate at least a 63A fuse. Normally this fuse is a neozed type. This switch-fuse is used to isolate the supply from the installation and also protects the distribution board itself from overloads and short circuits. The switch-fuse terminals can usually accommodate up to 35mm2 cable. A mechanical interlock prevents the closing of the switch until the fuse is firmly engaged in position. This provides a check against the possibility of the fuse being left loose, which could result in overheating, leading to a possible fire hazard. When the switch is off and the fuse withdrawn, it is not possible to touch any live parts. Some switch-fuses may have the supply connected to either the top or bottom terminal. Figure 28 illustrates one such switch-fuse with contacts in the closed position.

|

Figure 28.

Figure 29 illustrates a switch-fuse with contacts in the open position, with the fuse withdrawn. No live parts are accessible with supply connected to either top or bottom terminals.

|

Figure 29.

Normally an electrical installation will have a number of fuses or MCB’s connected in series. In the event of a fault occuring in the installation, only the protective device closest to the fault on the supply side, should operate. This means that other healthy circuits and equipment are unaffected.

A circuit designed in this way is considered to have ( good ) effective discrimination. Effective discrimination can be achieved by graded protection, since the speed of operation of the protective device increases as the current rating decreases.

Some fuses and circuit breakers are particularly fast in operation under fault conditions. Care must be taken to ensure that such devices are not used to protect circuits in which much slower-operating but lower rated devices are used. This could result in the main protective device operating rather than the faulty circuit protective device. Such an eventuality would be an example of poor discrimimation.

Figure30 illustrates effective discrimination in that, a fault occurring at point X should be interrupted by fuse C, leaving fuses A and B intact. Likewise a fault occurring at point Y should be interrupted by fuse B leaving fuse A intact.

|

Figure 30.

Source: http://local.ecollege.ie/Content/APPRENTICE/liu/electrical_notes/LL223.doc

Web site to visit: http://local.ecollege.ie/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes