Sort

Set-In-Order

Shine

Standardize

Sustain

A factory that has not adopted the 5-S’s is dirty with oil, dirt, and chips. Parts and boxes are lying around in non-designated areas; high precision equipment is bought, but not maintained. When a jig or fixture is needed, it cannot be found. The morale of associates is poor and the plant is doomed for trouble.

Here’s what 5-S means:

Here’s what 5-S means:

![]() Sort

Sort

Separate what is needed and what is not needed, and keep only those things that are needed in the workplace. Discard unnecessary items.

Set-In-Order

Neatly place and identify needed work items. Designate a place for every thing so that anyone can find it. Always put things back in their designated spots.

Shine

Clean up. Always maintain a clean and shiny

work place. Identify why things are getting dirty.

Standardize

Become a role model for adhering to the standards of the first three S’s and encourage others to follow them. Make rules and procedures to promote a good work environment until the first three S’s become everybody’s second nature.

Sustain

Sustain

Maintain and practice the first four S’s. Be thorough in straightening up, putting things in order and cleaning.

![]() OK, what happens when the 5-S’s are used?

OK, what happens when the 5-S’s are used?

5-S is the Top Salesperson

5-S is Thrifty

• A Neat and Clean Facility is thrifty and economizes on everything

5-S is the Engine of Safety

• A Neat and Clean Facility is spacious, bright, visibly appealing

• A Neat and Clean Facility is a much safer place to work

5-S is a Timekeeper

• A Neat and Clean Facility meets deadlines better

5-S Promotes Standardization

• Better communication results in better understanding of plans and decisions

• Visual presentation of instructions is widespread

• Associates can easily perform most operations

• Quality and cost are stabilized with clearly communicated goals

5-S creates an enjoyable workplace

5-S creates an enjoyable workplace

• Fewer troubles in a bright, clean workplace.

• More involvement of associates and more ideas for improvement

• New ideas are quickly adopted

• There is a spirit of improvement in the plant.

• A Get-It-Done attitude is the rule.

![]()

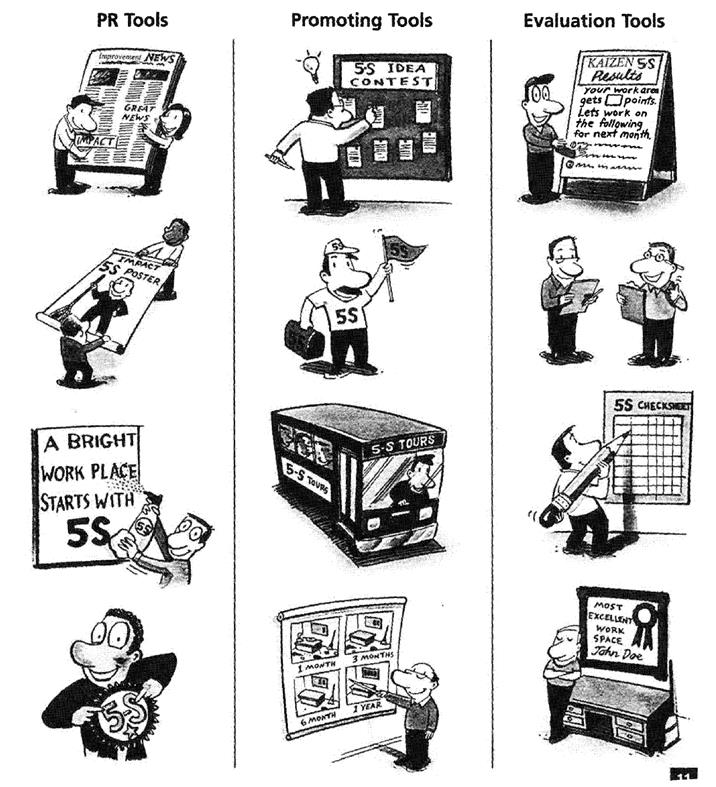

PROMOTING THE 5-S PROGRAM

Step 2 – Schedule Kaizen Activities within individual workcells

Step 3 - Maintaining the 5-S workcell

Sort:Separate what is needed and what is not needed, and keep only those things that are needed in the workplace. Discard unnecessary items.

Something used once a year would not be an everyday item. And we would not necessarily need all of the everyday items at once; but if lost, a replacement would be necessary.

The Key to Sorting

Sort does not mean that you throw out only items that you are sure you will never need. Nor does it mean that you arrange things into neat, straight patterns. When you sort, you leave only the bare essentials. When in doubt, throw it out!

Even after neatly arranging our tools, the proper tool can be difficult to find if we haven’t eliminated those which we don’t need. If we don’t get rid of things, we may not have room for the stuff we do need.

Before expanding, let’s think of organizing first!

![]()

We’ll be surprised at how spacious the plant becomes

Source: https://www.lean.org/FuseTalk/Forum/Attachments/Five%20S.doc

Web site to visit: https://www.lean.org/

Author of the text: indicated on the source document of the above text

If you are the author of the text above and you not agree to share your knowledge for teaching, research, scholarship (for fair use as indicated in the United States copyrigh low) please send us an e-mail and we will remove your text quickly. Fair use is a limitation and exception to the exclusive right granted by copyright law to the author of a creative work. In United States copyright law, fair use is a doctrine that permits limited use of copyrighted material without acquiring permission from the rights holders. Examples of fair use include commentary, search engines, criticism, news reporting, research, teaching, library archiving and scholarship. It provides for the legal, unlicensed citation or incorporation of copyrighted material in another author's work under a four-factor balancing test. (source: http://en.wikipedia.org/wiki/Fair_use)

The information of medicine and health contained in the site are of a general nature and purpose which is purely informative and for this reason may not replace in any case, the council of a doctor or a qualified entity legally to the profession.

The texts are the property of their respective authors and we thank them for giving us the opportunity to share for free to students, teachers and users of the Web their texts will used only for illustrative educational and scientific purposes only.

All the information in our site are given for nonprofit educational purposes